1. Overview of epoxy resin packaging technology

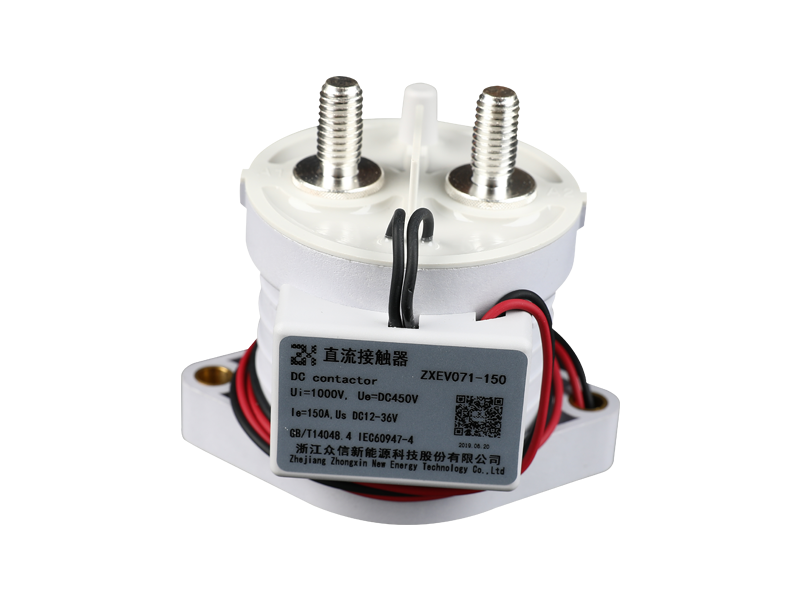

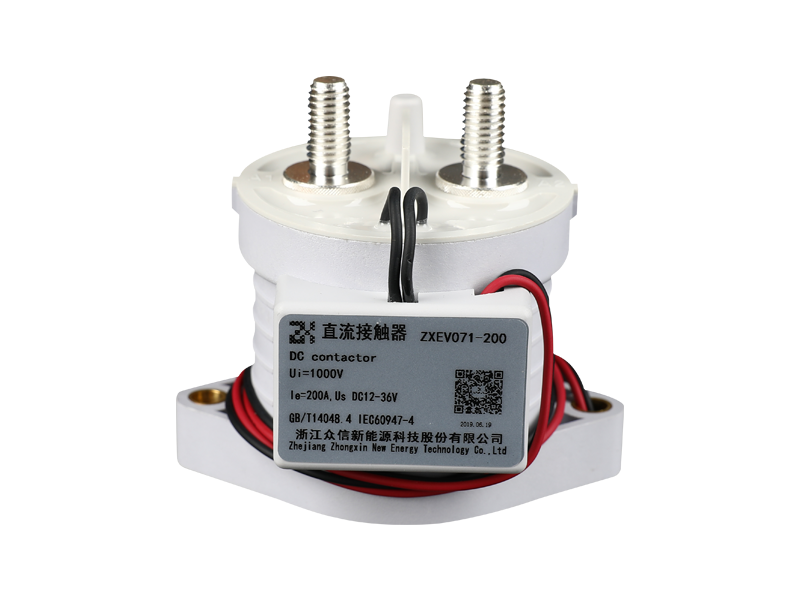

Epoxy resin is a thermosetting plastic that is widely used in the field of electronic packaging because of its excellent insulation, mechanical strength, chemical resistance and good packaging effect. In the manufacturing of medium-voltage DC contactors, epoxy resin packaging technology uses a specific process to completely wrap the internal circuits, contacts, coils and other key components of the contactor in epoxy resin materials, and fill them with water during the packaging process. Add an inert gas (such as nitrogen or argon) to create an oxygen-free, low-humidity internal environment. This packaging method effectively isolates moisture, oxygen, dust and other harmful factors in the external environment, thereby greatly extending the service life of the contactor.

2. Improve anti-aging ability and reliability

Epoxy resin encapsulation technology significantly improves the anti-aging capabilities of medium voltage DC contactors by providing a stable internal environment. Traditional contactors are often directly exposed to the external environment and are affected by temperature changes, humidity fluctuations, chemical corrosion and other factors for a long time, which can easily lead to problems such as contact oxidation and insulation material aging, thereby affecting the electrical performance and mechanical life of the contactor. After being encapsulated with epoxy resin, these environmental factors are effectively isolated, and the internal components can work in a more stable environment, thus significantly improving the overall reliability and durability of the product.

3. Ensure stable operation in harsh environments

In power systems, medium-voltage DC contactors often need to operate in various harsh environments, such as high temperature, high humidity, salt spray corrosion and other extreme conditions. Traditional contactors may experience reduced performance and increased failure rates in these environments, seriously affecting the stability and safety of the system. In contrast, epoxy resin encapsulation technology ensures the stable operation of the contactor in harsh environments through its excellent sealing and environmental adaptability. The filling of inert gas further enhances the protection effect inside the package, effectively prevents the failure of internal components due to oxidation and corrosion, reduces the failure rate caused by environmental factors, and improves the overall reliability and operating efficiency of the system.

4. Technological Innovation and Future Prospects

With the rapid development of new energy, smart grid and other fields, the performance requirements for epoxy medium pressure direct current contactors will become more stringent. Epoxy resin encapsulation technology is a key means to improve the performance of contactors, and its continuous innovation and optimization will be an inevitable trend in future development. For example, developing new epoxy resin materials to improve the heat resistance and weather resistance of the package; adopting more advanced packaging processes, such as vacuum infusion, high-pressure injection, etc., to further improve packaging efficiency and sealing performance; and exploring intelligent packaging technology, Realize online monitoring and health management of contactor status, further improving the intelligence level of the system.