Automotive relays are crucial components in modern vehicles, serving to control various electrical functions and systems. These relays are specifically designed and built to withstand the harsh and demanding conditions found in automotive environments. This article will explore the challenges that automotive relays face and the ways in which they are engineered to meet these challenges.

Harsh Automotive Conditions

Automotive environments are notorious for being challenging. Vehicles are exposed to extreme temperatures, humidity, vibrations, and mechanical stress. They must function reliably in a wide range of conditions, from frigid cold winters to scorching hot summers. Furthermore, the engine compartment can become a hostile place due to the presence of chemicals, such as oil and coolant, and electromagnetic interference from various electrical systems.

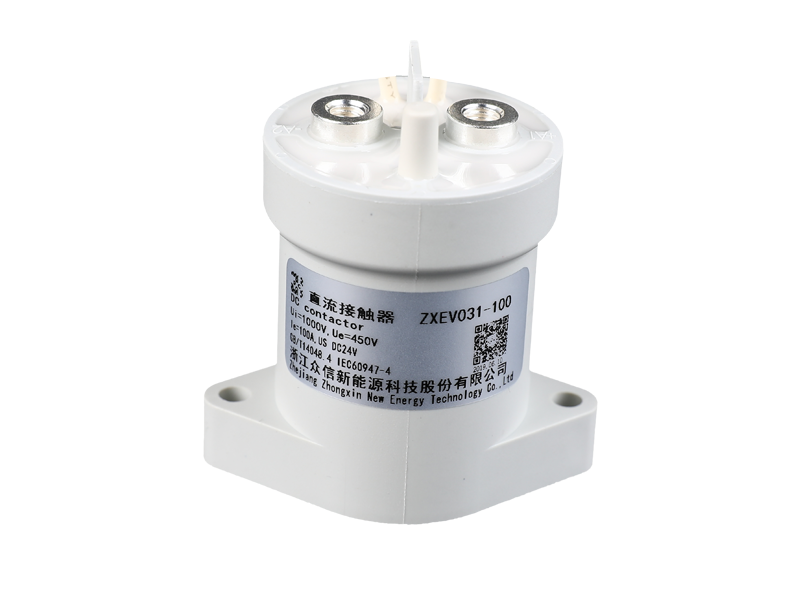

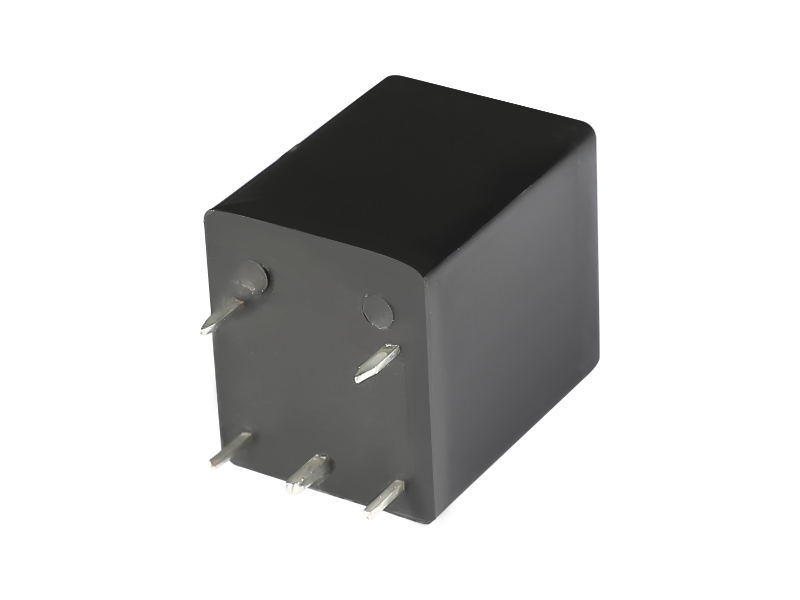

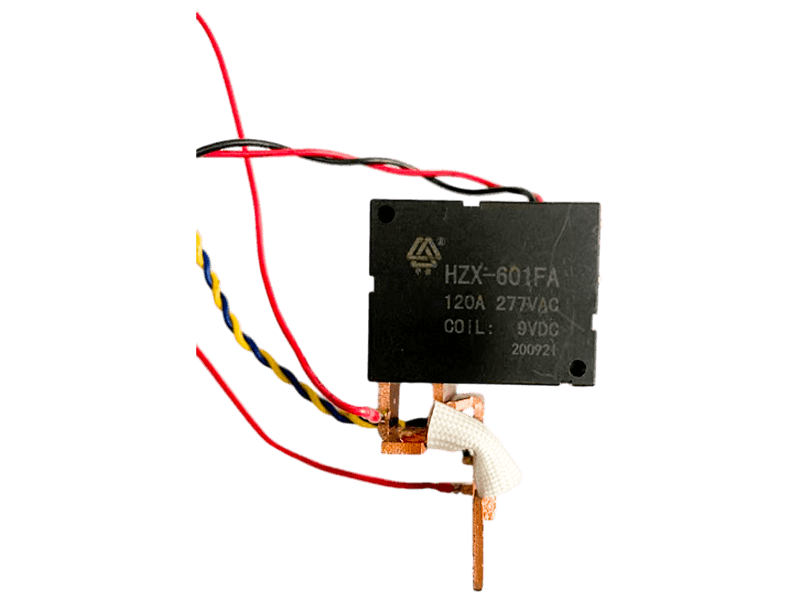

Relay Function in Vehicles

Relays play a pivotal role in vehicles. They act as remote-controlled switches that allow low-power signals to control high-power electrical circuits. For instance, when you turn on your car's headlights, a relay is used to handle the high current required by the headlight bulbs, preventing the need for thick and expensive wiring to run directly to the switch.

Engineering for Durability

To withstand these harsh conditions, automotive relays are meticulously engineered and tested:

Temperature Resistance: Relays are exposed to a wide temperature range in vehicles. They must operate in freezing conditions and continue functioning in extremely hot environments, such as the engine compartment. High-quality materials and thermal management are essential to ensure performance in such extremes.

Vibration and Shock Resistance: The continuous vibration and occasional shock loads from rough roads can cause electrical connections to loosen or fail. Automotive relays are designed with robust construction and secure mounting to withstand these mechanical stresses.

Corrosion Resistance: The presence of moisture, salt, and various chemicals in the automotive environment can lead to corrosion. Relays are often enclosed in sealed, moisture-resistant housings with specialized coatings to prevent corrosion.

EMI/RFI Protection: Electromagnetic interference and radio frequency interference from various vehicle components can disrupt relay operation. To mitigate this, relays are often designed with shielding and filtering to maintain signal integrity.

Dust and Debris Protection: Automotive relays must resist the ingress of dust and debris, which can hinder their operation. Gaskets and seals are used to keep contaminants out of the relay's critical components.

Waterproofing: In addition to protecting against dust and debris, many relays are designed to be waterproof or at least water-resistant, especially those installed in areas prone to exposure to rain or splash.

Electrical Load Capacity: Relays in vehicles must be capable of handling high current loads, such as those needed for fuel pumps, cooling fans, and high-intensity lighting. Special contact materials and design considerations are necessary to manage these loads effectively.

Electrical Contact Reliability: Over time, electrical contacts can wear out due to the constant switching required in a vehicle. High-quality relay designs incorporate materials and mechanisms that prolong the life of the electrical contacts.

Testing and Quality Control: Automotive relays are subjected to rigorous testing during production. This includes thermal cycling, vibration testing, and performance testing to ensure they meet strict quality standards and performance specifications.

Redundancy: In critical applications, automotive engineers may incorporate redundant relays to ensure that essential systems, such as the engine control module or airbag deployment, continue to function even if one relay fails.

Ingress Protection (IP) Rating: Automotive relays often have specific IP ratings that indicate their resistance to dust and water. Higher IP ratings indicate a greater level of protection.

Automotive relays are essential components in vehicles, allowing for the efficient and reliable control of various electrical systems. To endure the harsh conditions of the automotive environment, these relays are designed with a focus on temperature resistance, vibration and shock resistance, corrosion resistance, EMI/RFI protection, and more. The careful engineering and testing that goes into their design ensure that they can reliably function in the extreme conditions found in vehicles, contributing to the safety, performance, and longevity of modern automobiles.