High Voltage Direct Current (HVDC) contactors are electrical switching devices that are specifically designed to operate in high voltage and high current DC applications. They are typically used in power transmission and distribution systems, as well as in electric vehicles and other high power electronic applications.

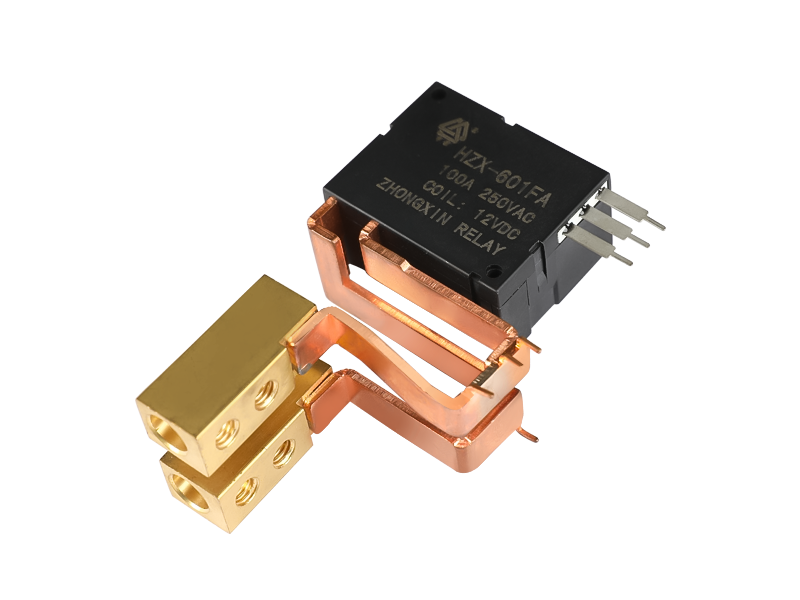

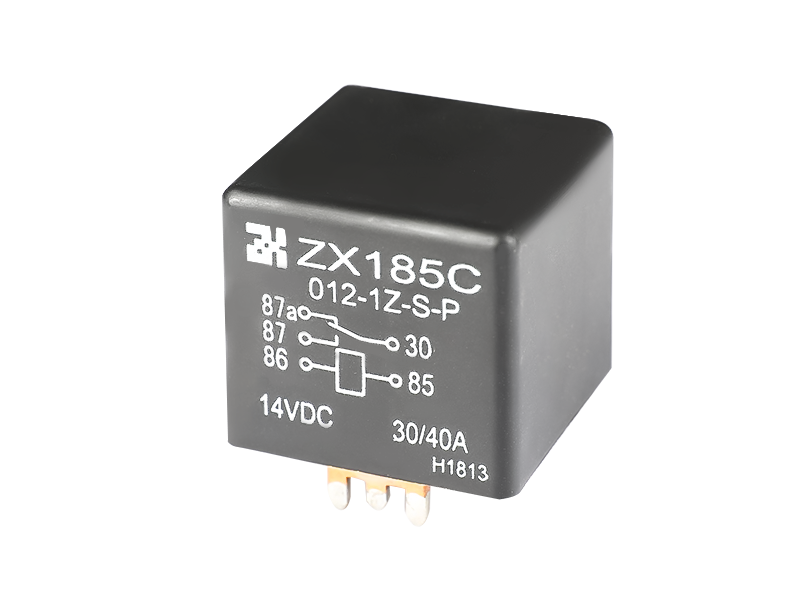

HVDC contactors are designed to handle high voltages and currents in DC circuits, and are typically larger in size than traditional AC contactors. They consist of a set of contacts that are used to make and break the DC circuit, as well as an actuating mechanism that is used to open and close the contacts.

The contacts of HVDC contactors are typically made from materials such as tungsten or copper, which have high conductivity and good resistance to arcing. The actuating mechanism can be either electromagnetic or hydraulic, depending on the application.

Function of HVDC Contactors

HVDC contactors are used to control the flow of high voltage and high current DC power in electrical systems. They are typically used in applications where traditional AC contactors cannot be used, such as in HVDC transmission systems.

The operation of an HVDC contactor is similar to that of a traditional AC contactor. When the contactor is energized, the contacts close and complete the DC circuit. When the contactor is de-energized, the contacts open and the DC circuit is broken.

Benefits of HVDC Contactors

HVDC contactors offer several benefits over traditional AC contactors. They are able to handle high voltage and high current DC circuits, which is important in applications such as HVDC transmission systems. They also have a longer lifespan than AC contactors, as DC circuits do not produce the same amount of arcing as AC circuits.

HVDC contactors are also more efficient than traditional AC contactors. They have a lower contact resistance and produce less heat, which can help to reduce power losses in the system. This is particularly important in high power applications where efficiency is a critical factor.

HVDC contactors are also designed to be reliable and durable. They are able to withstand harsh environmental conditions such as extreme temperatures, humidity, and vibration, which is important in many industrial and commercial applications.