Ceramic HVDC (High Voltage Direct Current) contactors are specialized electrical components designed to handle and switch high voltage levels in HVDC systems. HVDC technology is used for long-distance electricity transmission because it offers several advantages over traditional HVAC (High Voltage Alternating Current) systems, such as lower transmission losses and the ability to transmit electricity over very long distances.

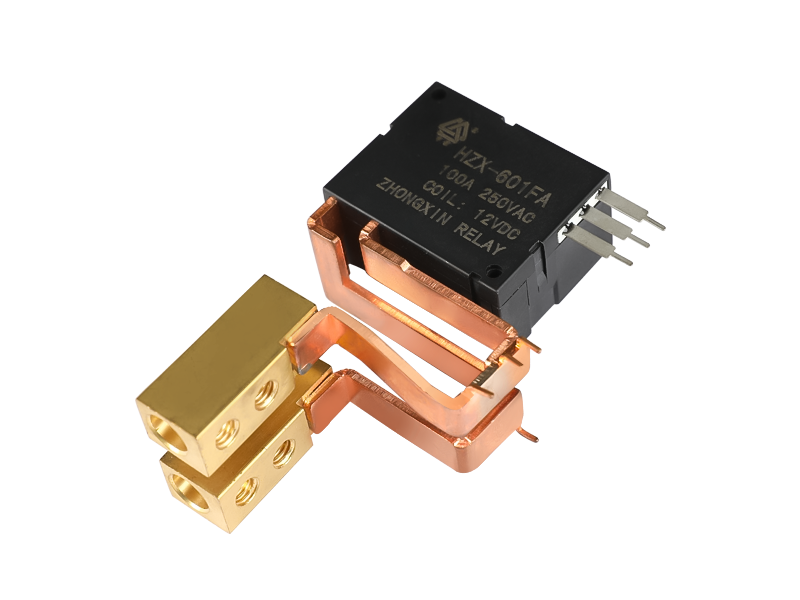

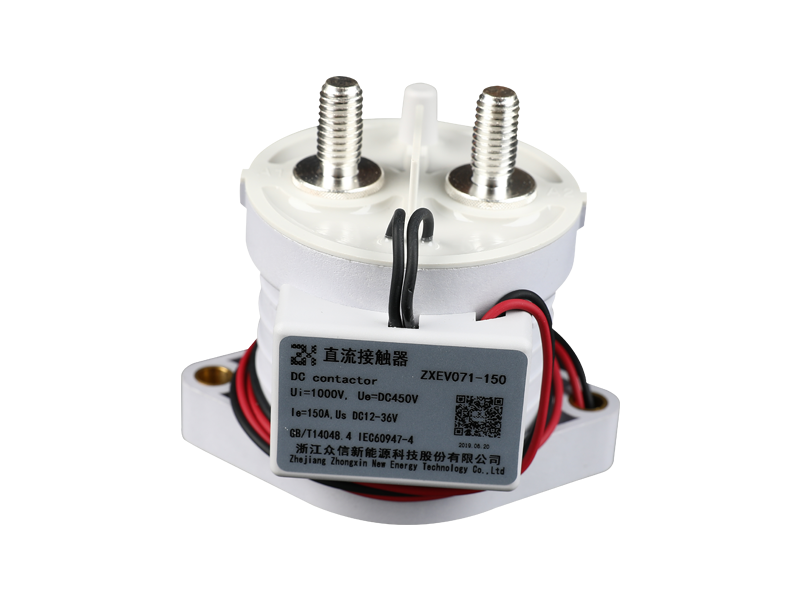

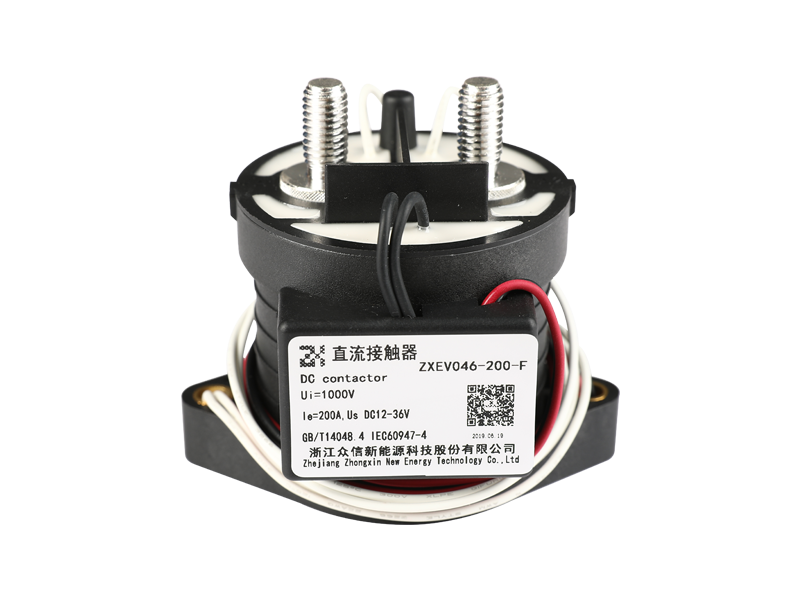

Ceramic HVDC contactors are used in HVDC systems for their ability to withstand the high voltage levels associated with these systems. These contactors are typically designed with high-quality insulating ceramics that can effectively insulate and isolate the electrical contacts, preventing electrical arcing and breakdown even under extreme voltage conditions. Some key features and characteristics of ceramic HVDC contactors include:

High Dielectric Strength: Ceramics have high dielectric strength, meaning they can withstand very high electric field intensities without breaking down. This property is crucial for HVDC applications where voltages can reach extremely high levels.

Low Conductivity: Ceramics are typically non-conductive materials, which is important for preventing leakage currents and maintaining the integrity of the insulation.

Thermal Resistance: Ceramic materials often have good thermal resistance, allowing them to handle high temperatures without degradation. This is important because electrical contacts can generate heat during switching operations.

Mechanical Durability: Ceramic HVDC contactors are designed to be mechanically robust to withstand the mechanical stresses associated with switching operations and the high voltages they are exposed to.

Arc Suppression: Ceramic contactors are designed to suppress electrical arcs effectively. When the contacts open or close, there is a potential for arcing, which can damage the contacts and disrupt the electrical circuit. Ceramic materials can help mitigate this issue.

Longevity: Due to their robustness and resistance to electrical breakdown, ceramic HVDC contactors are designed for long service life, making them suitable for high-reliability applications.

Ceramic High Voltage Direct Current Contactors are commonly used in high-voltage direct current applications such as HVDC transmission substations and converter stations. They play a crucial role in controlling the flow of electricity and ensuring the safe and reliable operation of HVDC systems. Their ability to withstand extremely high voltage levels is essential for maintaining the integrity of the electrical circuits and preventing electrical failures.