In the rapidly developing field of new energy vehicles, the power battery system is the "heart" of the vehicle, and its safety and reliability are directly related to the overall performance of the vehicle and the safety experience of the user. In this complex and sophisticated system, high-voltage relays undoubtedly play a vital role. They are like loyal guards, silently guarding the efficient operation and safety and stability of the power battery system.

1. The core function of high-voltage relays

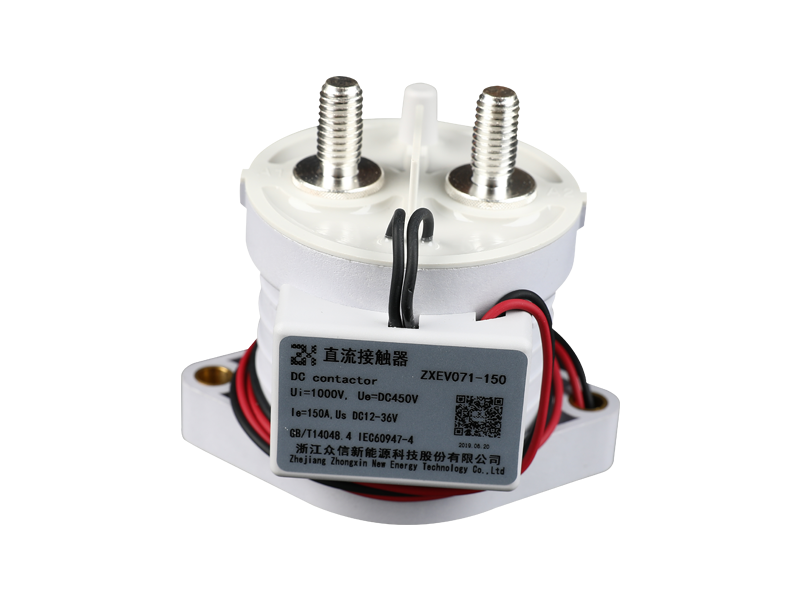

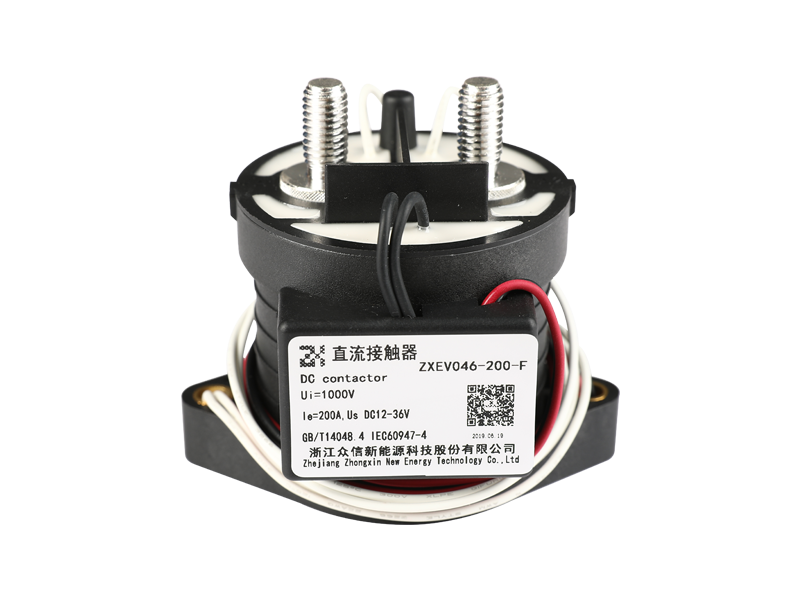

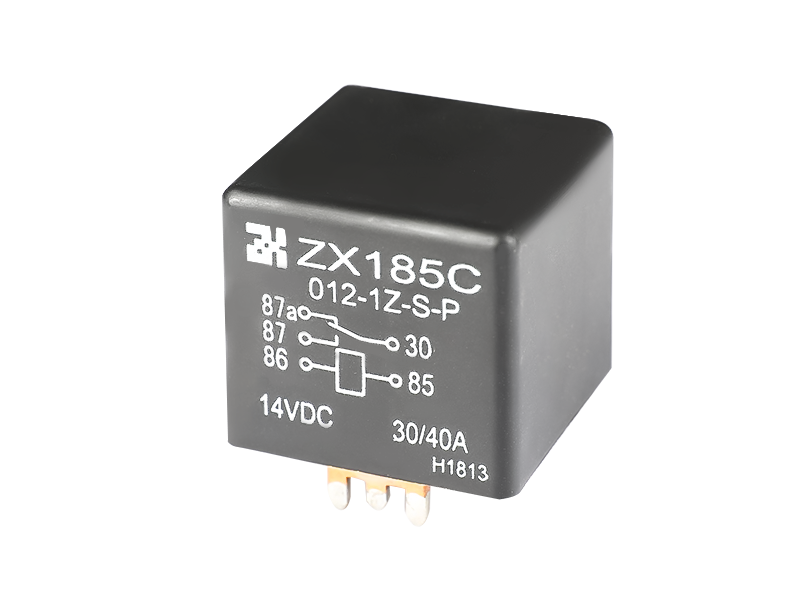

As an indispensable part of the power battery system, high-voltage relays mainly undertake the key tasks of high-voltage connection and disconnection. When the system is operating normally, these sophisticated electronic devices respond quickly to control instructions to ensure that high-voltage current can flow accurately to electrical equipment such as motors and controllers, providing continuous power support for the vehicle. This process requires high-voltage relays to have extremely high conductivity and reliable contact stability to cope with high-voltage and high-current working environments.

2. Safety barrier during failure

However, electric vehicles will inevitably encounter various emergencies during driving, such as system failures and collision accidents. At this time, the role of high-voltage relays is particularly important. Once the system detects an abnormal situation or receives a disconnection command, the high-voltage relay will quickly and accurately cut off the high-voltage electrical system, effectively preventing the current from continuing to flow, thereby avoiding serious consequences such as short circuits, fires, and even explosions. This decisive "brake" at a critical moment builds an indestructible safety line for the driver and the vehicle itself.

3. Technological innovation promotes performance improvement

With the continuous advancement of new energy vehicle technology, high-voltage relays are also continuously iterating and upgrading. Modern high-voltage relays are not only more sophisticated in material selection, but also use special materials that are resistant to high temperatures and corrosion, which improves the durability and safety of the product; at the same time, significant progress has been made in intelligence and integration. By integrating advanced sensors and control systems, high-voltage relays can achieve more accurate status monitoring and fault warning, further improving the overall performance and safety of the power battery system.

4. Future Outlook

Looking to the future, with the continuous expansion of the new energy vehicle market and the continuous innovation of technology, the importance of high-voltage relays as one of the core components of the power battery system will become more prominent. With the rapid development of materials science, electronic technology and intelligent manufacturing technology, we have reason to believe that high-voltage relays in the future will be more miniaturized, lightweight and intelligent, providing a more solid guarantee for the safe and efficient operation of new energy vehicles.

As the safety guardian of the power battery system, the importance of high-voltage relays is self-evident. They not only ensure the normal operation of the vehicle, but also provide reliable safety protection for drivers and passengers at critical moments. With the continuous advancement of technology and the continuous expansion of the market, we have reason to expect that high-voltage relays will play a more important role in the field of new energy vehicles in the future.