An

Epoxy Medium Pressure DC relay is designed to deal with medium voltage and present day degrees. It is normally utilized in commercial and electricity distribution systems in which medium voltages are required. In this text, we will talk the running principle of an Epoxy Medium Pressure DC relay and the way it handles medium voltage and contemporary ranges.

To recognize how an Epoxy Medium Pressure DC relay works, it is crucial to have a primary understanding of relays. A relay is an electromechanical device that operates through the use of an electromagnet to control the glide of current in a circuit. It includes a coil, armature, and contacts. When modern flows through the coil, it generates a magnetic discipline, which pulls the armature and closes or opens the contacts, depending at the relay's layout.

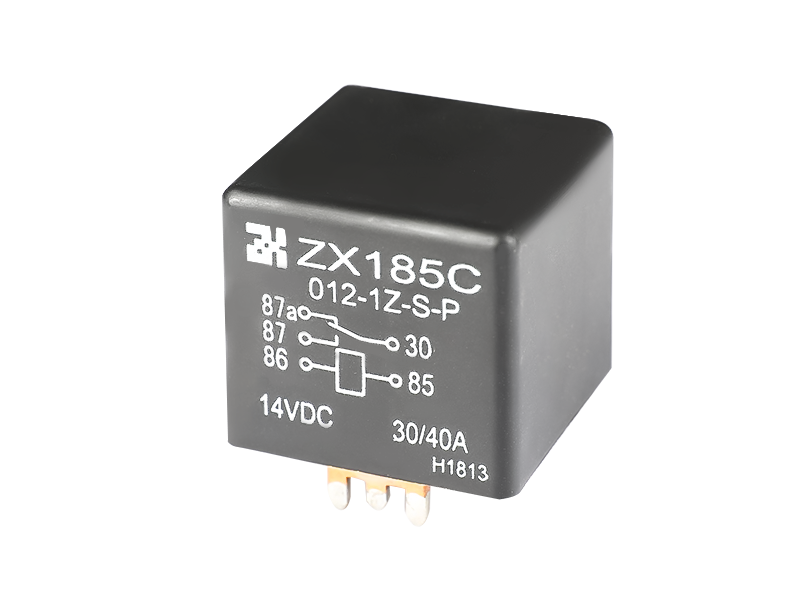

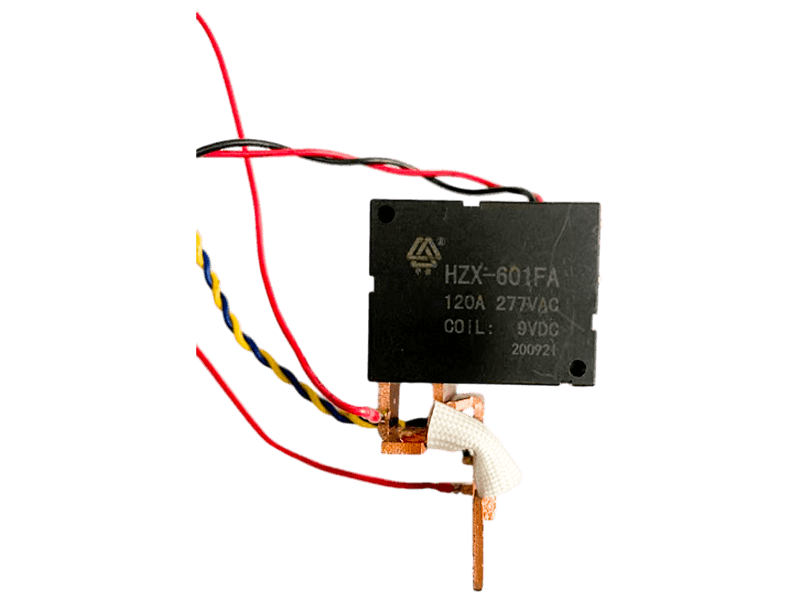

An Epoxy Medium Pressure DC relay is particularly designed to function using direct modern (DC) at medium voltage ranges, usually starting from 1000V to fifteen,000V. It is constructed using wonderful materials that may face up to high voltages without arcing or shorting.

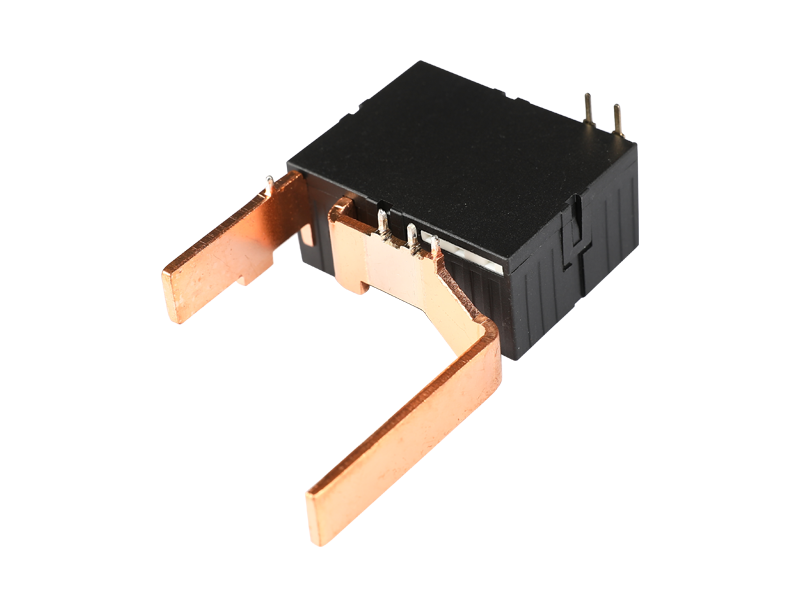

The coil used in an Epoxy Medium Pressure DC relay is made of copper wire and is wound round an iron middle. When a cutting-edge flows via the coil, it generates a magnetic subject, which pulls the armature closer to it. The armature is commonly product of magnetic cloth and is attached to a movable touch.

The movable touch is connected to the armature and movements at the side of it whilst the magnetic area is generated. When the armature moves, it either closes or opens the constant contacts, relying on the relay's layout and the manipulate signal it receives.

In the case of medium voltage and present day degrees, the contacts of an Epoxy Medium Pressure DC relay are mainly designed to address excessive voltages and currents without arcing or excessive wear. The contacts are made from incredible materials like silver or silver alloy, that have wonderful electric conductivity and might resist high temperatures generated all through the switching operation.

Furthermore, the contacts in an Epoxy Medium Pressure DC relay are plated with materials like gold or palladium to reduce contact resistance and save you the formation of oxide layers, which could have an effect on the relay's performance. The contact plating also provides corrosion resistance, making sure lengthy-time period reliability and strong operation.

To cope with the medium voltage stages, an Epoxy Medium Pressure DC relay is geared up with an insulation machine that could face up to the excessive electric pressure among the contacts and the encompassing structure. The relay's housing is fabricated from epoxy resin, which has incredible electric insulation residences, and it is specially designed to inhibit the formation of partial discharges that might damage the relay.

Additionally, the coil and other internal components are carefully insulated to prevent voltage breakdown and make certain safe operation. The insulation gadget additionally helps to shield the relay from moisture, dirt, and other environmental elements, making sure dependable performance in harsh conditions.

In end, an Epoxy Medium Pressure DC relay is designed to deal with medium voltage and cutting-edge levels in industrial and power distribution systems. It is built the usage of super materials and geared up with an insulation system to resist high voltages, prevent arcing, and ensure safe and dependable operation. With its strong layout and superb electrical characteristics, an Epoxy Medium Pressure DC relay is a critical issue in medium voltage applications.