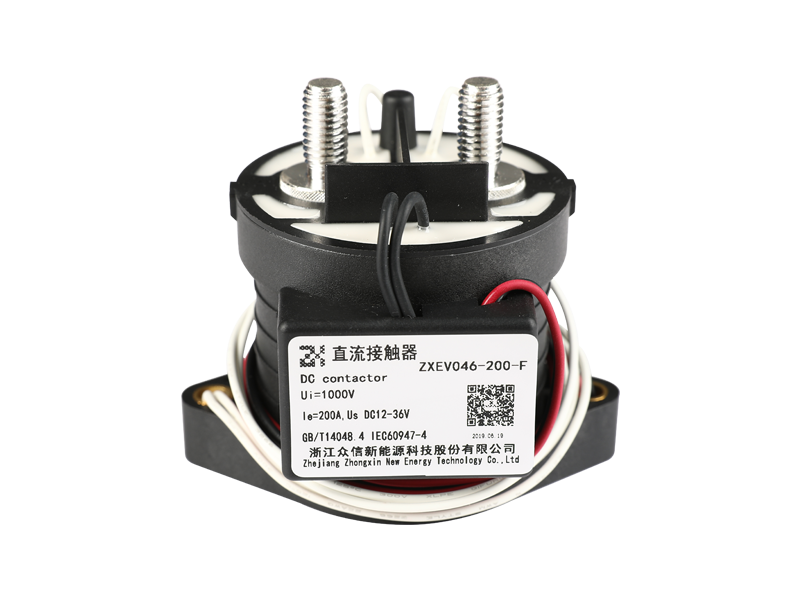

The temperature and environmental situations have a huge impact on the operation and lifespan of ceramic excessive voltage DC contactors. These factors can affect diverse elements of the contactor's overall performance, which includes its electrical properties, mechanical power, and overall reliability.

One of the primary concerns with temperature is the impact it has on the electrical houses of the contactor. Ceramic substances used in high voltage DC contactors have confined temperature tolerance. High temperatures can cause expanded resistive losses and reduced dielectric strength, that can impact the contactor's common performance and overall performance. Excessive warmness can motive the contactor to overheat, main to multiplied wear on the contacts and potentially ensuing in contact welding or unfavourable the insulation substances. It is important to operate the contactor within its special temperature variety to ensure most effective performance and save you untimely failure.

Environmental situations, which include humidity and pollution, can also effect the contactor's operation and lifespan. High humidity tiers can motive moisture ingress and result in insulation degradation, electrical breakdown, or even brief circuits. Pollution, which includes dust, dirt, or chemical substances, can acquire on the contact surfaces, increasing contact resistance and doubtlessly inflicting contactor malfunction. In places with high ranges of pollution, common cleaning and preservation can be required to make sure proper operation and save you premature failure.

In addition to temperature and environmental conditions, the contactor's cooling mechanism plays a important position in preserving its top of the line operating temperature. Proper cooling is important to deplete warmness generated for the duration of operation and preserve the contactor within its temperature limits. Some ceramic contactors may additionally depend upon air cooling, in which the encircling air cools the contacts and different additives. In greater disturbing programs, liquid cooling structures may be hired to decorate cooling performance.

The lifespan of a

ceramic high voltage DC contactor is at once impacted through temperature and environmental conditions. Prolonged publicity to high temperatures or hot temperature cycling can boost up the growing older processes of the contactor's substances, which include thermal enlargement and contraction, leading to mechanical stress and capacity material fatigue. Environmental conditions, which includes humidity and pollution, also can accelerate fabric degradation and decrease the contactor's overall lifespan.

To ensure an prolonged lifespan, several measures can be taken. First, the contactor must be operated in the precise temperature and humidity variety. Regular inspection and cleaning of the contact surfaces, in addition to preservation of cooling structures, will limit the impact of environmental situations. Proper installation, along with sufficient clearances and insulation measures, also can make contributions to the contactor's longevity.

In summary, temperature and environmental conditions have a huge effect on the operation and lifespan of ceramic high voltage DC contactors. Maintaining the contactor inside its specified temperature variety, controlling humidity stages, and preventing pollution buildup are essential for most excellent performance. Proper cooling and regular renovation additionally play a essential position in stopping untimely failure and ensuring a longer lifespan for the contactor.