Magnetic latching relays are useful for switching applications in a variety of situations, and they have many benefits over their mechanical counterparts. They tend to draw less power and are generally less bulky. They also tend to have a longer lifespan. The switching action performed by magnetic latching relays is fast, and the devices have a lower power consumption than mechanical variants.

When designing magnetic latching devices, it is important to consider the magnetic properties of both the permanent magnet and the ferromagnetic material. These factors can affect the latch force. It is also important to consider the presence of ferromagnetic materials such as soft steels or magnets, as these can introduce additional variables and affect the magnetic latch force.

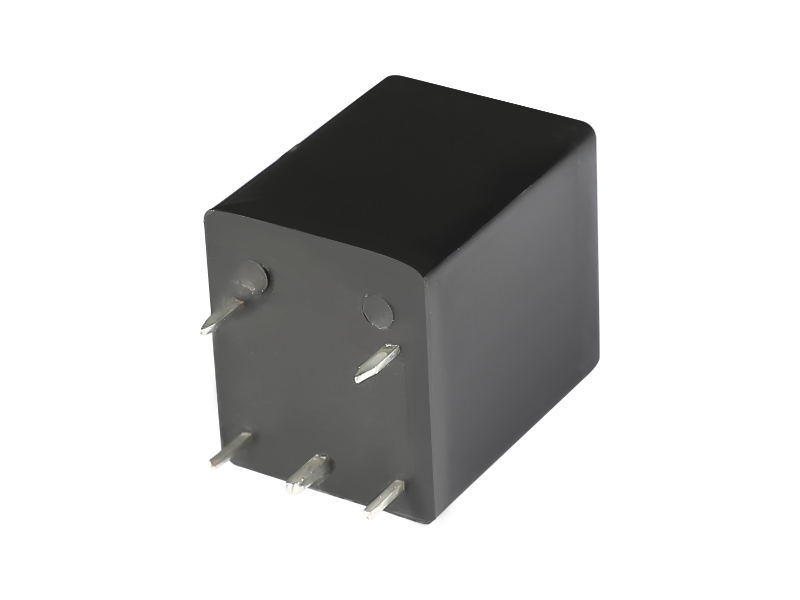

Magnetic latching relays are composed of two layers: an upper layer that has an electromagnetic system, and a lower layer that has a contact system. The upper layer is made up of the electromagnetic system, which consists of a magnet, coils, and an armature. The armature is in a U-shaped iron core that sits above the coil. The magnet holds the armature in place, allowing the current to be switched from one circuit to another.

Magnetic latching solenoids are made from permanent magnets. They are able to dissipate a lot of power with the same voltage. However, the plunger does not automatically return to its original position when the magnetic force is negated. Therefore, it is important to make sure that the magnetic latching solenoid is properly loaded before it is installed.

Magnetic latching solenoids are used for a variety of applications. In addition, to push, pull, and hold applications, they are also available in bidirectional magnetic latching open frame versions. The bi-directional version can electromechanically power a load in either direction. This makes them an ideal choice for continuous duty applications.

Magnetic latching solenoids are a popular choice for home and daily equipment as well as for security. The internal permanent magnet maintains the magnetic attraction when the plunger is not under any force. This means that the magnetic latching solenoid uses a minimal amount of power to restore attraction. The main advantage of magnetic latching solenoids is that they are inexpensive and easy to install.

Magnetic latching solenoids are linear devices that use permanent magnets to hold the plunger when not in use. This makes them a good choice for applications that require low power, but high levels of reliability. In addition to their low power, these magnetic latching solenoids are also available in C-Frame and D-Frame configurations and offer both push and pull actions. Standard duty cycles for magnetic latching solenoids range from 10% to 42% when energized.

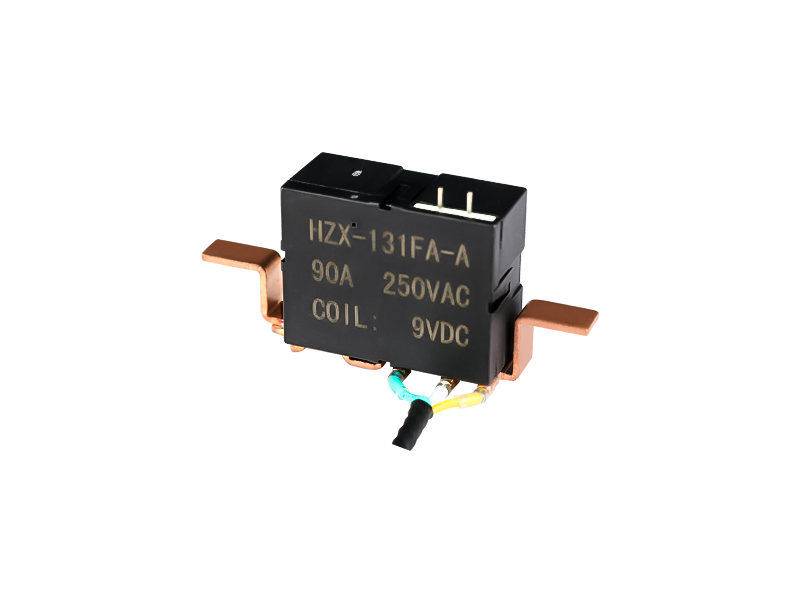

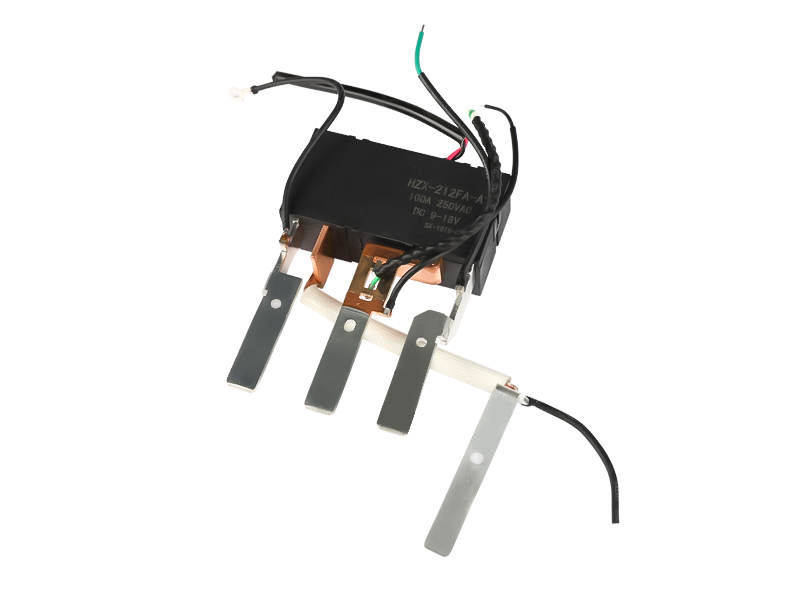

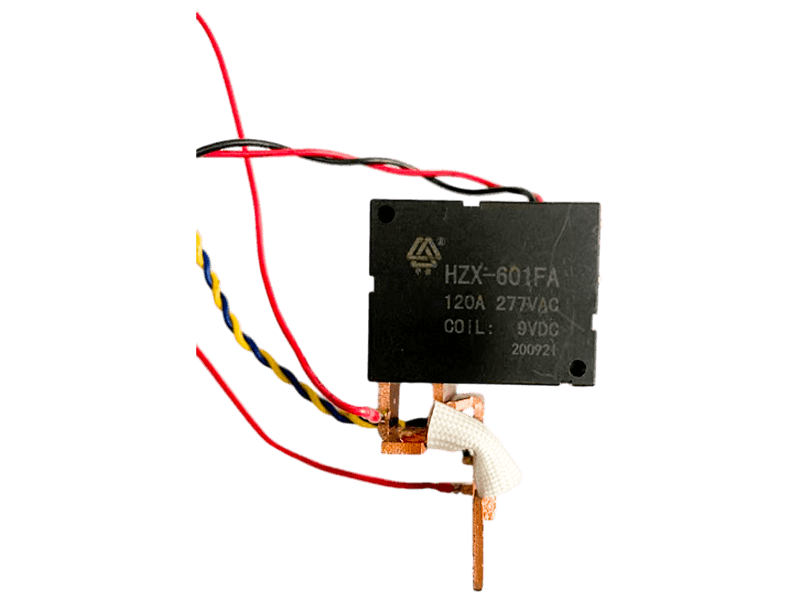

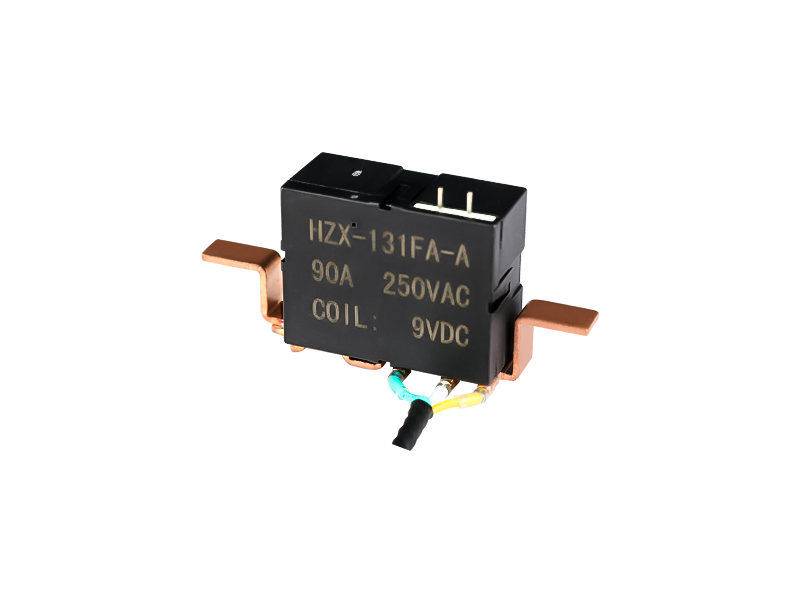

90A switching capability

Very minimal power consumption from the coil

9mm creepage distance

4KV dielectrics strength coil to contact

In accordance with IEC62055-31:UC2

Outline dimensions:(36*30*16.5)mm

CE,CQC compliant

RoHS,UL compliant