The noise of the

AC contactor in operation is very large, which can be dealt with as follows:

1. The power supply voltage is insufficient, and the suction force of the electromagnet is not enough to generate noise. Try to increase the voltage of the operating circuit.

2. The magnetic system is improperly assembled or skewed by vibration or the parts are stuck, and the iron core cannot be leveled, resulting in noise. This system should be adjusted during processing to identify and eliminate the cause of the inflexibility of the mechanism.

3. The pole surface is rusted or foreign matter (such as grease, dust, flower hair, etc.) invades the pole surface of the iron core. At this time, the pole surface of the iron core should be cleaned.

4. Electromagnet noise is generated due to excessive contact spring pressure. Usually, the contact spring pressure can be adjusted.

5. Noise is generated due to the rupture of the short-circuit ring, and the iron core or the short-circuit ring should be replaced.

6. The pole surface of the iron core is excessively worn and uneven, and the iron core should be replaced.

7. The coil is short-circuited between turns, and the coil is usually replaced.

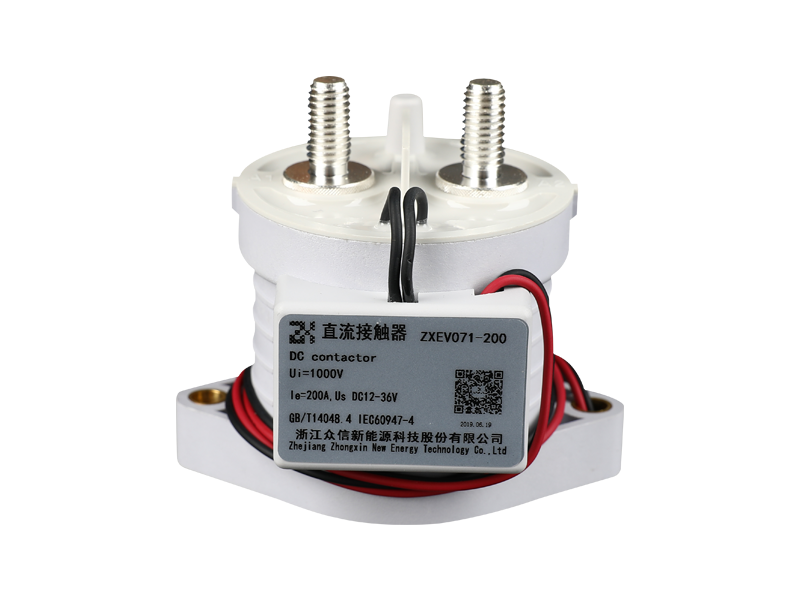

1. Small and lightweight:Internally adopt reliable sealing technology and filled with nitrogen which arc colling ability is high. It can cut off high voltage DC in a short time.

2. High contact reliability:Due to the contact sealed in the nitrogen, therefore it will be not oxidized, also achieving the contact of the dustproof and waterproof.

3. Safety and reliable:Use the professional explosion-proof structure design,to achieve a high degree of security,adopt magnetic quenching helps to cut-off the DC load quickly.

4. Application:DC charging pile, electric vehicles, hybrid vehicles, battery charging and discharging system,Photovoltaic power generation system such as dc high voltage application.

English

English