If you've ever wondered what exactly a

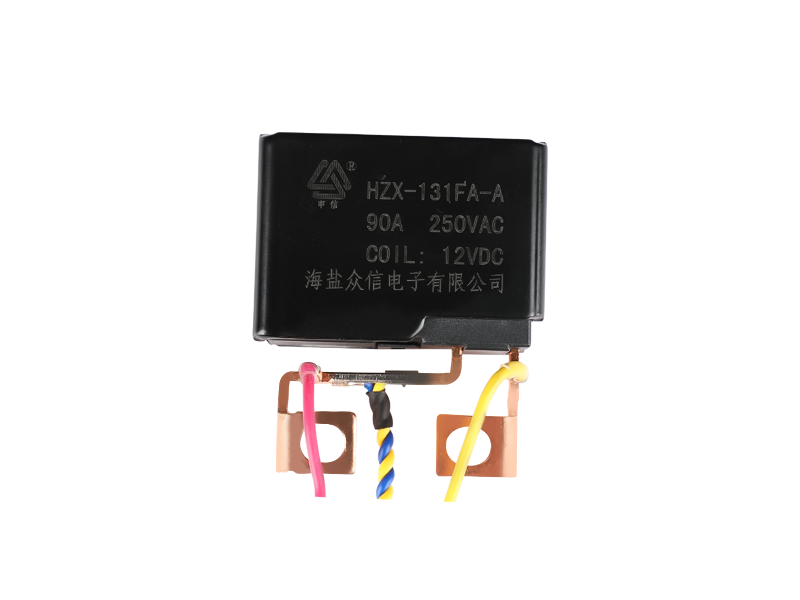

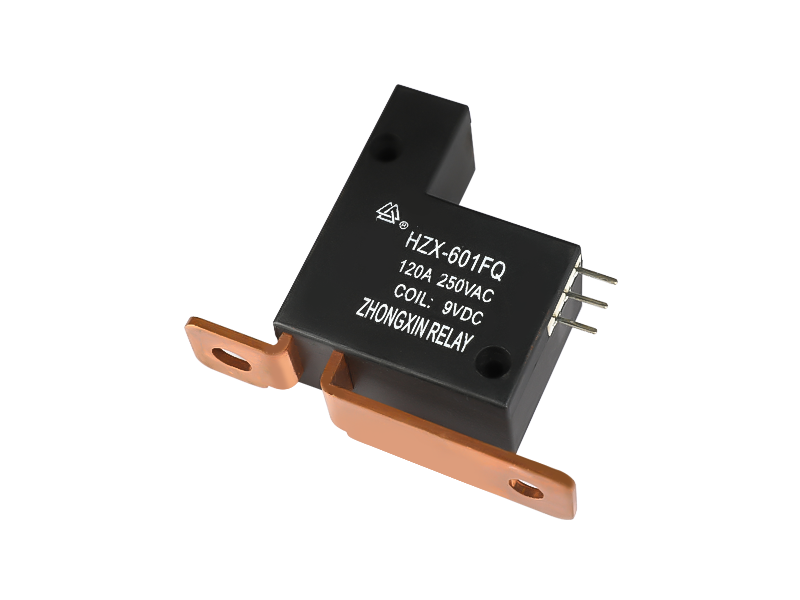

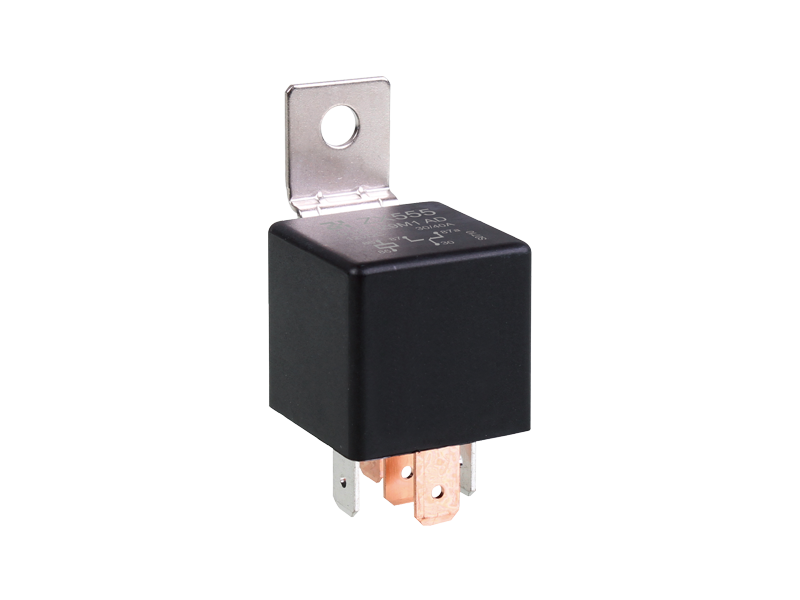

Magnetic latching relay is, read on to learn more. A Magnetic latching relay is a type of electrical switch that uses magnets to latch a circuit. It functions by attracting a magnet to the armature and reversing its polarity when a switch is turned on. Because of this, the device is insensitive to vibration and shock. Because of this, the device doesn't require much power to stay in its latched position. It also doesn't require any fine balance of magnetic forces because the force holding the armature in place is completely independent of the strength of the magnet field.

The main difference between a magnetic latching relay and a conventional electrical relay is the power required to open or close its contacts. A magnetic latching relay essentially works by relying on magnetic attraction to hold its contacts open or closed. The power it draws from the coil will cause it to move in one direction and reset once the polarity is reversed. The two-coil model allows polarized current to progress through both coils.

A magnetic latching relay has a maximum contact switching current of 150A. Its voltage drop is below 100mV. The maximum contact switching current of a magnetic latching relay depends on the type of steel used for the control coil. A high carbon content steel will provide a more secure latch. A low Rockwell hardness will have little or no effect on the latching characteristics. When considering buying a Magnetic Latching Relay, remember to read the manual and use it accordingly.

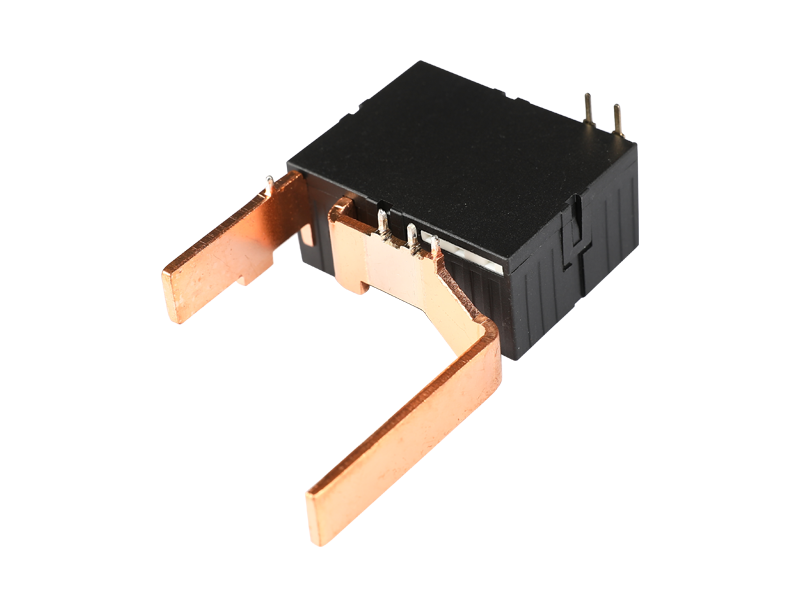

The magnetic latching relay has an asymmetrical solenoid structure. The first fixed iron core 52 of the relay contacts a coil 31 when the relay is open. When the switch is closed, the movable iron core 21 moves upward. This mechanism allows the latching device to latch a circuit. A magnetic latching relay has many advantages. Its unique construction and functionality make it a popular choice for many different types of electronic and electrical applications.

The magnetic latching relay is composed of two main components: the armature and the movable contact. The movable contact is mounted along the armature and is biased by the contact spring into contact with the fixed one when the armature is in its first position. The second part is mounted swingably to the frame and is connected to the armature by means of a blocking member. The blocking member acts as a rigid strut between the armature and the frame.