What is the difference between electromagnetic relay and solid state relay

Update:03-11-2021

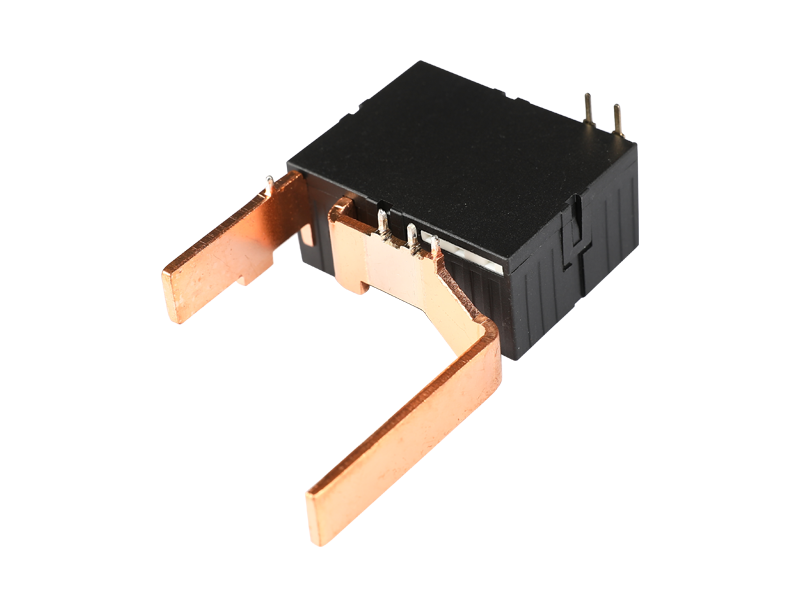

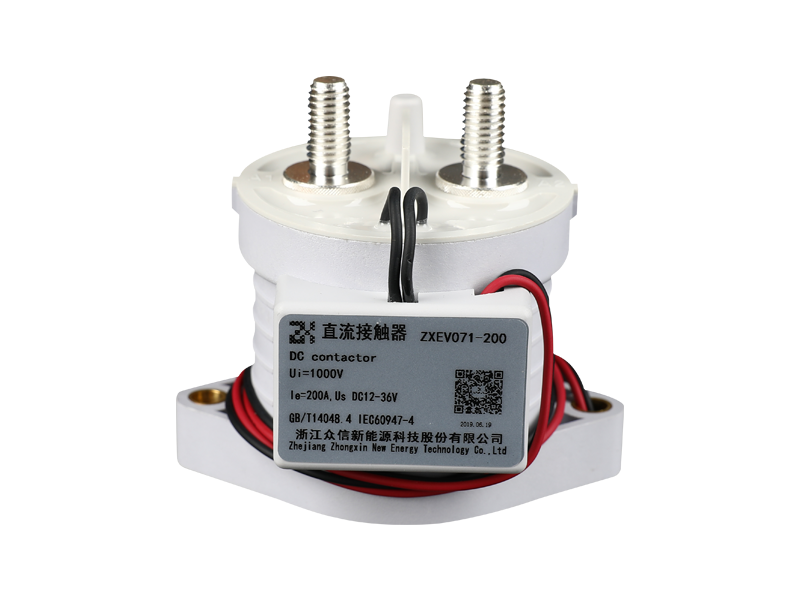

Electromagnetic relay: The working principle of the electromagnetic relay is the principle of electromagnetic induction. The structure of a mechanical relay is very classic, and it has hardly changed since its invention. It consists of two parts: a coil and a contact.

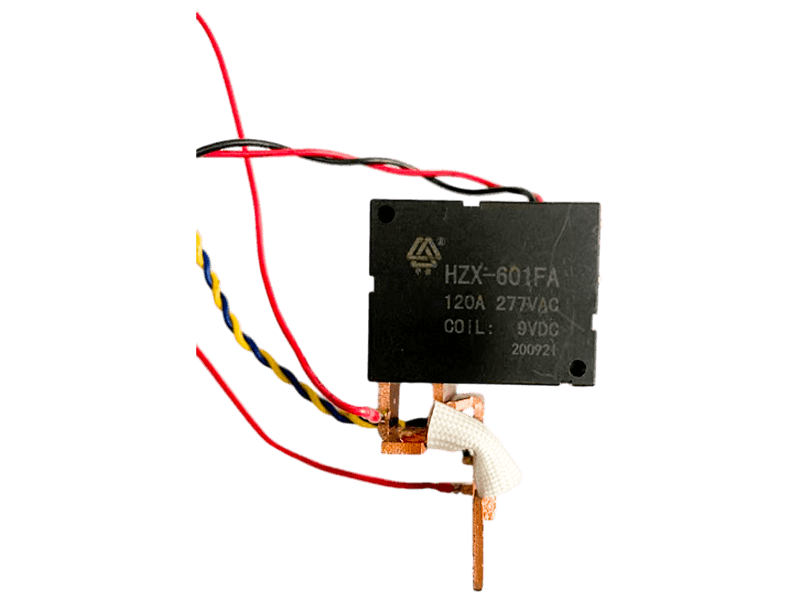

Solid-state relays: With the development of science and technology, the demand for relays (small size, long service life, high stability, high performance and high compatibility) is increasing, so semiconductor components are used as switching elements in relays. There are no mechanical contacts and coils in this relay, which is different from traditional mechanical relays.

The advantages and disadvantages between electromagnetic relays and solid-state relays

Electromagnetic relay

advantage

Compatible with AC and DC current; support multiple contacts; contacts can be normally open or normally closed; cheap; small size; low residual voltage; no need for a radiator; no leakage current.

shortcoming

Contact vibration; high control power, usually higher than 200mW; limited contact life; limited maximum switching frequency (5-10mhz); noisy operation; digital loop interface required; poor working capacity for large currents, which will cause arcing; during operation During this period, electromagnetic interference (EMI) is generated; the switching actions cannot be completely synchronized.

solid state relay

advantage

Anti-vibration; anti-shock; anti-corrosion; moisture-proof; switch mode can be asynchronous or synchronous; compatible with digital circuits; fast response time; low control power, usually 10-50mW; long life, 50-100 times that of electromagnetic relays; synchronous Low electromagnetic interference (EMI) in switch mode; no mechanical strain; no mechanical moving parts; no noise in movement.

shortcoming

Leakage current; not suitable for small output signals; only one contact; output can only be DC or AC, the two are not compatible; residual voltage 1-1.6v; usually a radiator is required.