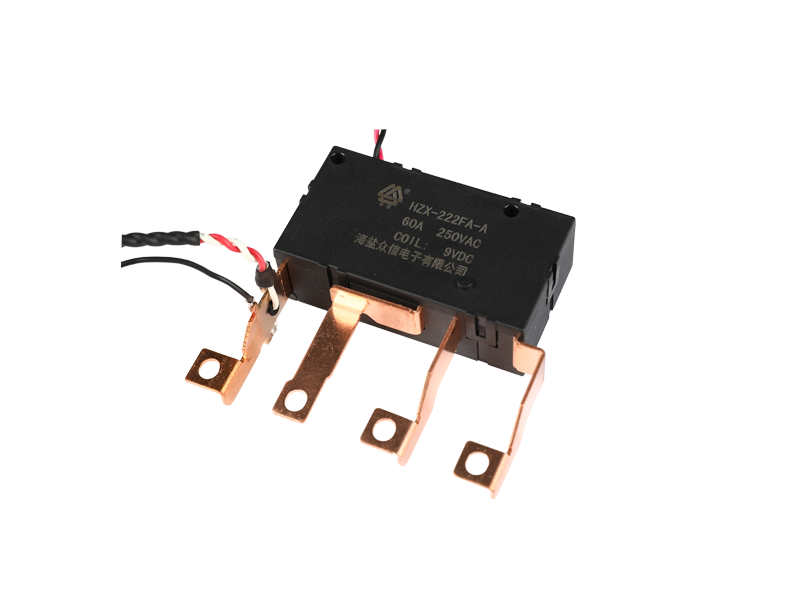

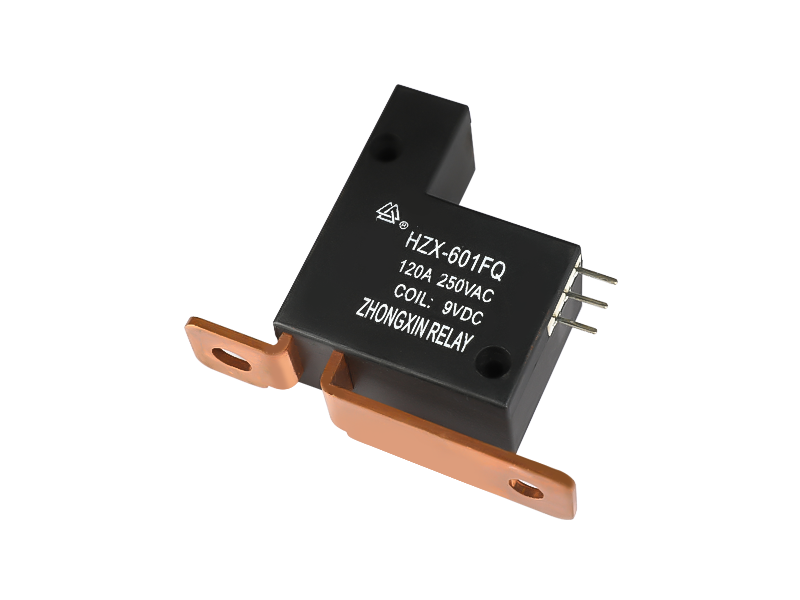

Relay, as a common electrical control element, plays a vital role in automation equipment and power systems. It is usually composed of a precise combination of core components such as electromagnet, armature, contact spring and spring. These components work together to achieve reliable control of the circuit.

First, let's take a closer look at the various components of the relay. Electromagnet, as a key component for generating a magnetic field, is usually composed of a coil and an iron core. When voltage is applied to both ends of the coil, current passes through the coil, thereby generating a magnetic field. This magnetic field is the fundamental driving force for driving the relay. The armature is a component that can move under the action of a magnetic field. It is usually made of soft magnetic material so that it can be easily magnetized and moved in a magnetic field. The contact spring is the component in the relay that is responsible for the on-off of the circuit. It is usually composed of one or more pairs of metal sheets. When the armature moves, it will drive the opening and closing of the contact spring, thereby controlling the on-off of the circuit. The spring plays a reset role. When the electromagnet is powered off, the tension of the spring will restore the armature to its initial position, the contact spring will also be disconnected, and the circuit will return to the disconnected state.

Next, let's take a closer look at the circuit control process of the relay under the electromagnetic effect. This process can be divided into the pull-in stage and the release stage.

In the pull-in stage, when we apply voltage to both ends of the coil of the electrical relays, a current will be generated in the coil. When this current passes through the coil, a magnetic field will be generated. This magnetic field will act on the armature, causing it to be magnetized and generate magnetism. Under the action of the magnetic force, the armature will overcome the tension of the spring and move toward the iron core. This movement process will drive the closing of the contact spring, so that the working circuit can be energized. The closure of the contact realizes the opening of the circuit, and the current can be transmitted to the load device through the relay to start working.

In the release stage, when the voltage at both ends of the coil is cut off, the current in the coil disappears, and the magnetic field disappears. At this time, the armature loses the attraction of the magnetic field, and the tension of the spring will restore it to its initial position. This movement process will drive the disconnection of the contact spring, so that the working circuit is powered off. The disconnection of the contacts realizes the closure of the circuit and the stop of the load equipment.

Relays are widely used in circuit control. It can be used to realize functions such as remote control, automatic control and protection control of circuits. For example, in power systems, relays can be used to monitor electrical quantities such as current and voltage, and cut off the circuit when the electrical quantity exceeds the set value to protect power equipment and personal safety. On automation equipment, relays can be used to control the start, stop and turn of the motor to realize the automatic operation of the equipment.

As an important electrical control component, relays play an irreplaceable role in modern production and life. By deeply understanding the working principle of relays and the circuit control process under electromagnetic effects, we can better apply relays to realize reliable control and automatic operation of circuits.