1. Overview of epoxy potting technology

Epoxy potting technology is a technology that uses epoxy resin as a packaging material to seal electronic components or assemblies through a specific process. Epoxy resin has excellent insulation properties, chemical corrosion resistance, mechanical strength and thermal stability, and can maintain stable performance in harsh environments such as high temperature, low temperature or humidity. Therefore, epoxy potting technology is widely used in the packaging and protection of electronic products to improve their reliability and service life.

2. Application of epoxy potting technology in high-voltage DC contactors

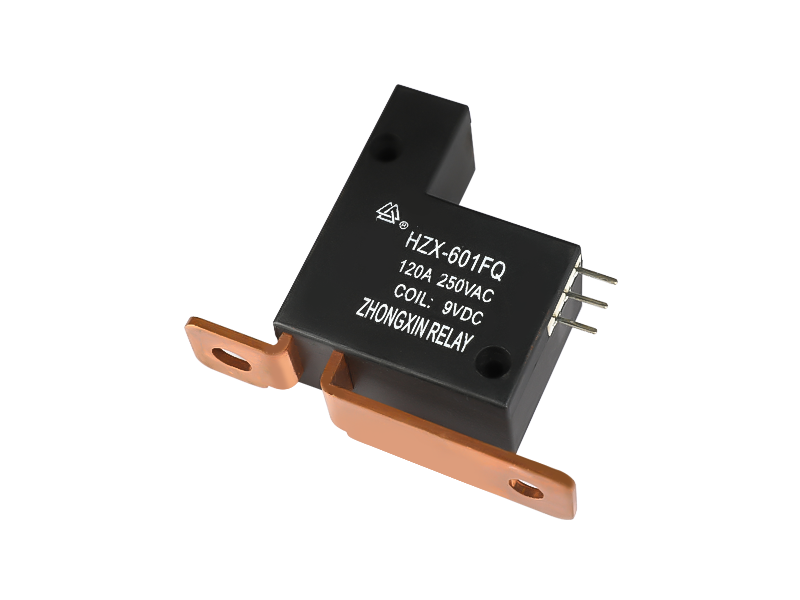

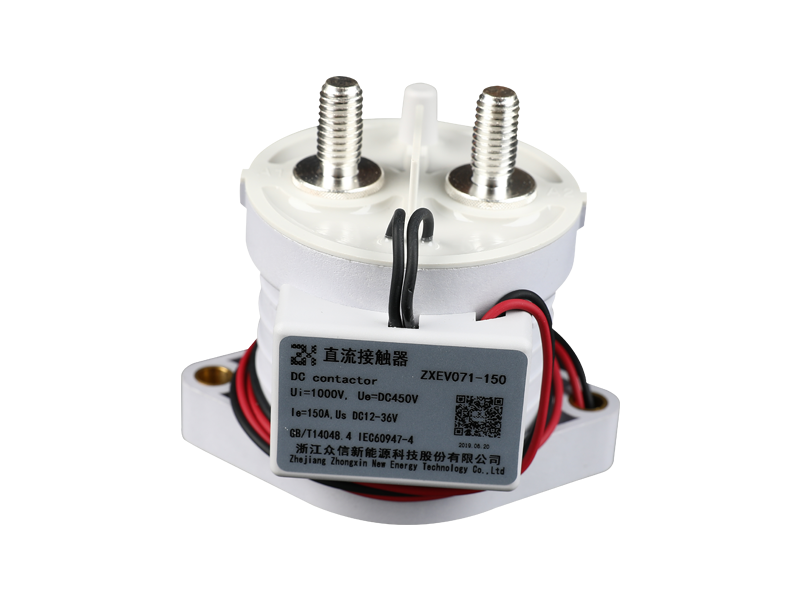

As a key component for connecting and disconnecting DC circuits in power systems, the protection and packaging of high-voltage DC contactors is particularly important. Epoxy potting technology achieves effective protection of contacts by injecting epoxy resin into the interior of the contactor, tightly encapsulating the contacts and other key components together.

In new energy vehicles, high-power DC contactors are key components of the main circuit, pre-charging circuit, fast charging circuit and slow charging circuit of the battery pack, and are responsible for connecting the battery pack with motors, controllers and other components. Due to the complex and changeable working environment of new energy vehicles, such as high temperature, low temperature, humidity, vibration, etc., the reliability and stability of DC contactors are extremely high. The application of epoxy potting technology not only improves the insulation performance and anti-aging ability of the contactor, but also enhances its dustproof, waterproof and shockproof performance, thereby ensuring the safe and efficient operation of electric vehicles.

3. Advantages of epoxy potting technology in new energy vehicles

Improving insulation performance: Epoxy potting technology can significantly improve the insulation performance of high-voltage DC contactors, prevent insulation failure caused by external factors such as dust and moisture, thereby reducing the risk of circuit failure.

Enhancing anti-aging ability: Epoxy resin has excellent anti-aging properties and can resist the influence of environmental factors such as ultraviolet rays, high temperature and low temperature on contactors, prolonging their service life and reducing the cost of replacement and maintenance.

Improving stability: Epoxy potting technology can enhance the stability and reliability of high-voltage DC contactors, so that they can maintain normal operation in various harsh environments, thereby ensuring the safety and stability of electric vehicles.

Dustproof and waterproof: Epoxy potting technology can also effectively prevent dust and moisture from entering the interior of the contactor, avoiding circuit short circuits and failures caused by dust accumulation and moisture erosion.

Anti-vibration performance: Epoxy resin has good anti-vibration performance and can buffer and absorb vibration energy, thereby protecting the contactor from vibration damage.