In today's rapidly developing energy field, energy storage systems, as a key part of the modern energy system, are gradually showing their irreplaceable importance. They are like "regulators" in the energy field, able to silently accumulate energy during low periods of power demand and quickly release it during peak periods, thereby balancing grid load, optimizing resource allocation, and significantly improving energy utilization efficiency. In this complex and sophisticated energy storage system, ceramic high-voltage DC contactors, with their unique advantages, have become the guardians of ensuring stable operation of the system.

Core requirements for energy storage systems

Energy storage systems serve as a bridge between renewable energy and end users. The stability and efficiency of their performance directly affect the security and efficiency of the entire energy network. Especially in large-scale energy storage applications, how to quickly and accurately control the charge and discharge process of energy storage battery packs has become the focus of technical research. In addition, the energy storage system also needs to have high reliability to ensure that it can maintain excellent performance under long-term operation, while reducing maintenance costs and improving overall economic benefits.

The unique value of ceramic high voltage DC contactors

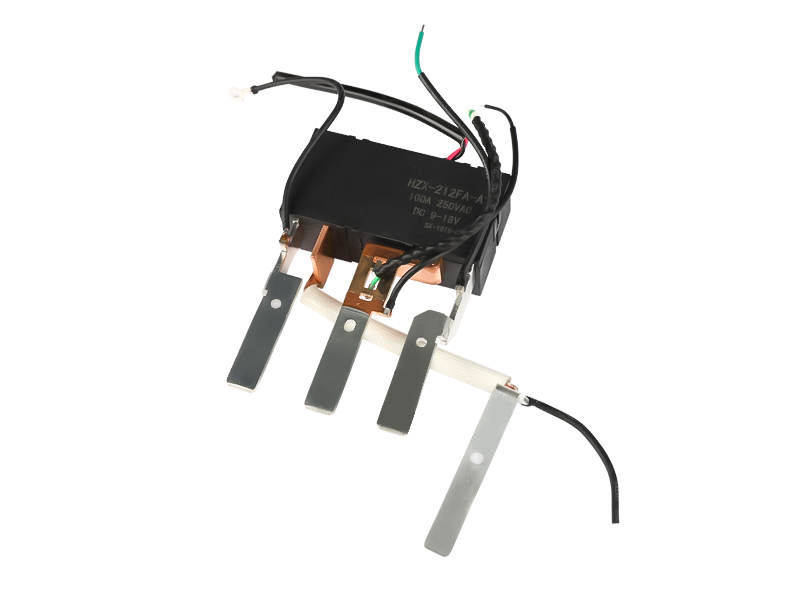

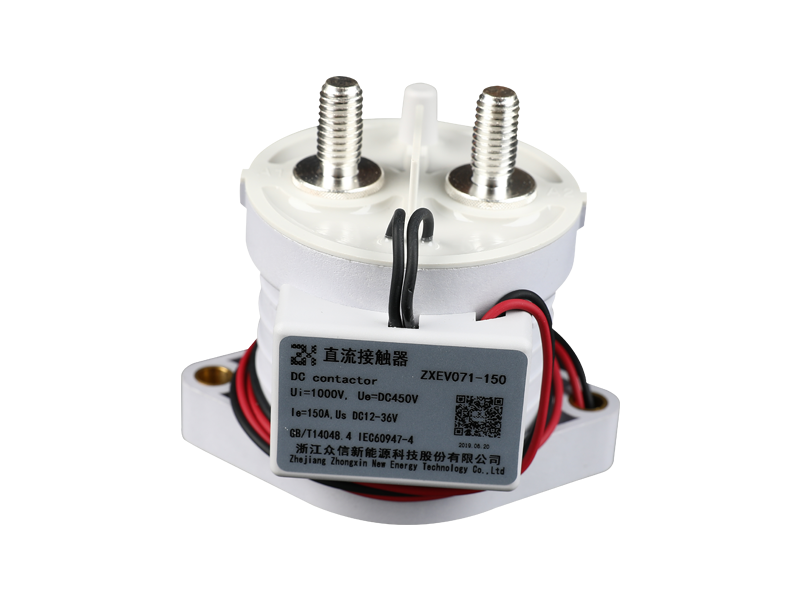

It is against this background that ceramic high-voltage DC contactors stand out due to their excellent performance and become a key component in energy storage systems. First of all, its rapid response capability enables the energy storage battery pack to quickly adapt to changes in grid load and achieve precise dispatch of electric energy. Whether it is the charging process during low power demand periods or the discharging process at peak times, ceramic high-voltage DC contactors can ensure smooth charging and discharging, thereby maintaining the stable operation of the energy storage system.

Secondly, the application of ceramic materials gives high-voltage DC contactors high reliability and long life. Compared with traditional materials, ceramics have better insulation properties and arc resistance, and can maintain stable performance in harsh working environments. This means that the energy storage system can operate with greater confidence, reducing downtime and maintenance costs caused by equipment failure. At the same time, the high wear resistance of ceramic materials also extends the service life of the contactor, further reducing the overall operating cost of the system.

Key factors driving the development of energy storage systems

The application of ceramic high-voltage DC contactors in energy storage systems not only improves the stability and efficiency of the system, but also promotes the development of the entire energy storage industry. As the proportion of renewable energy continues to increase and smart grid construction accelerates, the market demand for energy storage systems will continue to grow. As an important component of the energy storage system, the ceramic high-voltage DC contactor's technological innovation and industrial upgrading will directly affect the overall performance and market competitiveness of the energy storage system.

Strengthening the research, development, application and promotion of ceramic high-voltage DC contactors is of great significance for promoting the development of energy storage systems, improving energy utilization efficiency, and promoting energy transformation. In the future, with the continuous advancement of technology and further reduction of costs, ceramic high-voltage DC contactors are expected to be applied in a wider range of fields and contribute more to the development of modern energy systems.