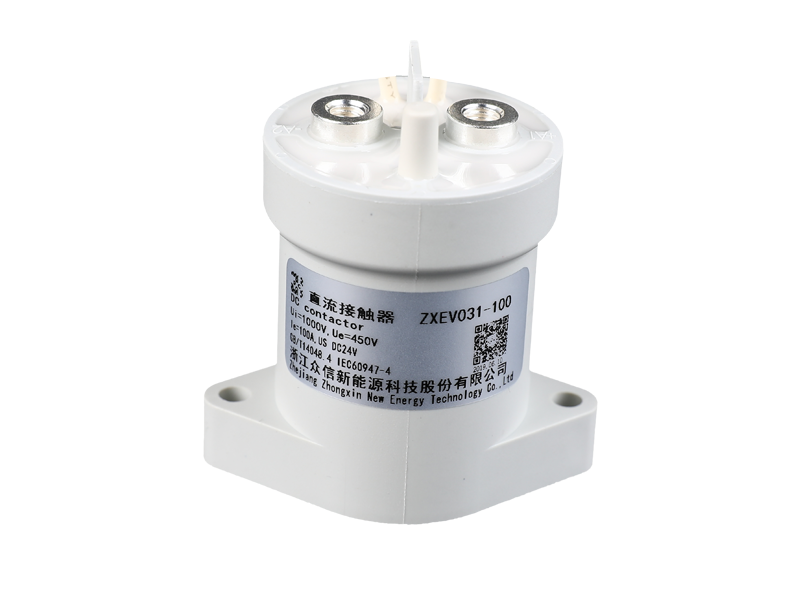

Ceramic excessive voltage direct modern-day (HVDC) contactors play a essential position in the green transmission and distribution of electric electricity. These contactors are in particular designed to deal with high voltages and provide dependable switching answers for HVDC packages. Their effect on energy performance and strength loss may be analyzed from several perspectives, which include their layout, cloth homes, and operational traits.

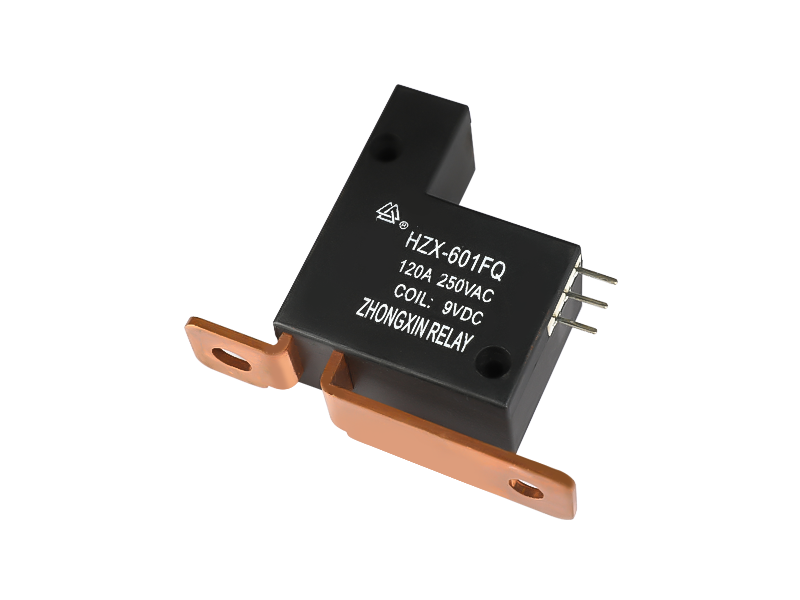

Firstly, the design of

Ceramic High Voltage Direct Current Contactors specializes in minimizing power loss and improving strength performance. By using low-resistance materials and optimizing the contact floor region, these contactors make sure efficient transmission of electrical contemporary. The use of ceramics, which might be regarded for his or her low electric resistivity, facilitates to decrease the resistance and therefore reduce electricity losses in the course of operation. Additionally, the proper design of the contactor housing and systems allows to prevent leakage currents and reduce electricity wastage.

Secondly, the cloth residences of ceramics make a contribution to strength efficiency by means of reducing losses. Ceramics have extremely good insulation houses, allowing them to withstand excessive voltages with out breakdown. This high dielectric power minimizes the risk of electrical arcing, ensuing in decrease energy losses during switching operations. Furthermore, the low thermal conductivity of ceramics reduces warmness dissipation, helping to enhance electricity efficiency by means of reducing thermal losses.

The operational characteristics of ceramic HVDC contactors additionally impact energy performance and strength loss. HVDC structures are known to have decrease losses compared to excessive voltage alternating modern (HVAC) systems, and ceramic contactors enable green switching of HVDC circuits, thereby further minimizing power losses. Their capability to handle excessive voltages and switching frequencies complements system overall performance and contributes to universal power efficiency.

Furthermore, the lifespan and protection necessities of ceramic HVDC contactors also affect power efficiency. With proper installation and normal renovation, the contactors can keep their overall performance over an extended duration. This reduces the want for common replacements and associated electricity intake. Additionally, the sturdy design and high sturdiness of ceramics permit them to face up to harsh environmental conditions, lowering ability faults and failures that may result in energy losses.

It is crucial to be aware that at the same time as ceramic HVDC contactors provide full-size advantages for electricity performance and strength loss discount, other factors in the HVDC device, inclusive of the overall device layout, conductors, and insulation materials, also influence those elements. The integration of various additives, together with transformers, converters, and filters, within the HVDC machine should be cautiously considered to make sure choicest energy performance and minimize strength losses.

In conclusion, ceramic HVDC contactors have a tremendous impact on strength performance and energy loss discount in excessive voltage direct present day systems. Their green design, low-resistance materials, high-quality insulation residences, and operational traits make contributions to minimizing energy losses at some stage in switching operations. By enhancing power efficiency and reducing energy losses, ceramic HVDC contactors play a important position in the effective transmission and distribution of electric strength.