High Voltage Direct Current Contactors are specialised gadgets designed to address the switching and manipulate of excessive voltage currents in HVDC structures. These structures generally transmit strength over lengthy distances, imparting advantages together with reduced transmission losses and expanded power switch capability in comparison to standard alternating modern-day (AC) systems. HVDC contactors play a essential function in ensuring the green and secure operation of HVDC structures.

The dealing with of excessive voltage currents involves numerous challenges, inclusive of insulation requirements, arc extinction, and control circuitry. HVDC contactors are specially designed to address those challenges and offer reliable switching and manage functionality. In this text, we can speak the key factors and ideas utilized in HVDC contactors.

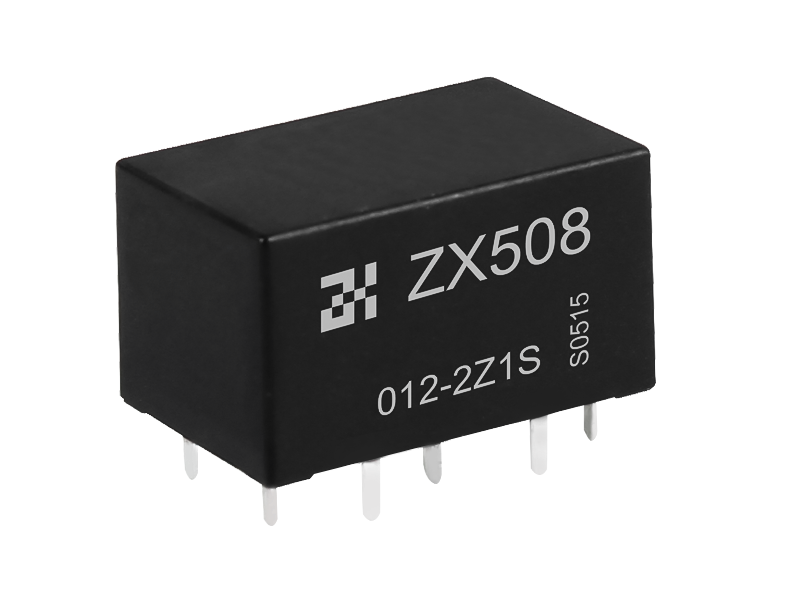

1. Insulation: HVDC contactors want to offer powerful electrical insulation to save you voltage breakdown and make certain safety. They are commonly encapsulated in an insulating fabric, which include epoxy resin, to save you any leakage modern or flashover. The insulating components are designed to withstand the high voltage degrees and provide a dependable barrier among the high voltage and coffee voltage parts of the contactor.

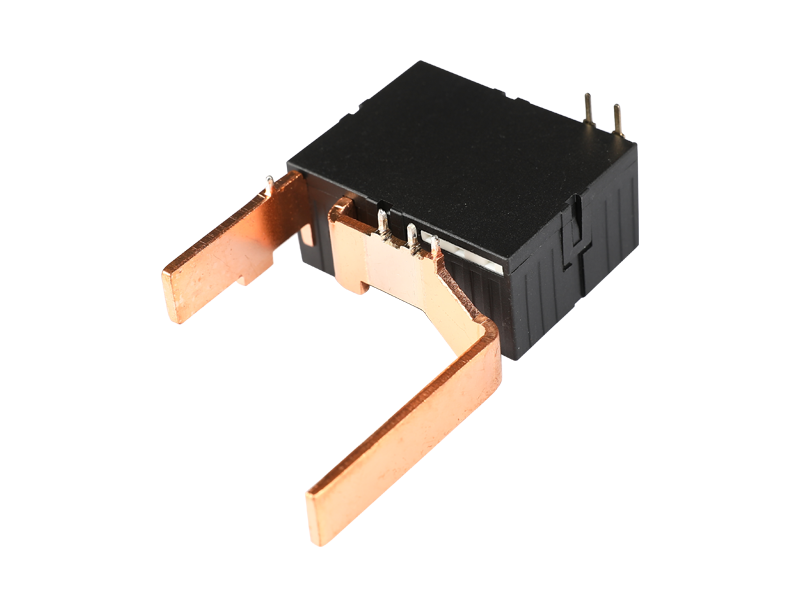

2. Contact material and layout: HVDC contactors rent specialized contact materials able to withstanding excessive voltage and present day ranges without immoderate wear or degradation. Common touch substances consist of silver alloys or tungsten-copper composites. The contacts are engineered to offer low contact resistance and minimize voltage drop, decreasing power losses in the course of operation. The touch design also bills for the unique requirements of HVDC systems, which include arc extinction necessities and the potential to withstand excessive fault currents.

3. Arc extinction: When high voltage currents are interrupted, an electric powered arc may additionally form among the contacts, that may result in damage and decreased contact life. HVDC contactors hire diverse strategies to extinguish these arcs successfully. One commonplace approach is the use of magnetic blowout, wherein a magnetic discipline generated via a coil forces the arc to rotate, elongate, and then extinguish. The arc energy is dissipated, allowing the contactor to securely open with out excessive put on or damage.

4. Control circuitry: HVDC contactors require sophisticated control circuitry to make sure particular and dependable switching operations. The manipulate circuitry monitors the gadget parameters, along with voltage, current, and temperature, and triggers suitable switching movements. It frequently consists of protective relays to stumble on and respond to odd conditions, such as overcurrent, overvoltage, or DC line faults. The manage circuitry additionally ensures synchronized switching between more than one contactors during device operation and protection.

5. Auxiliary structures: HVDC contactors are usually followed by using auxiliary structures to assist their operation. These can include cooling systems to deplete heat generated for the duration of high modern-day switching, mechanical interlocks to prevent incorrect or dangerous switching sequences, and tracking structures to provide real-time facts on contactor status and performance.

Overall, HVDC contactors play a vital role in the switching and manage of excessive voltage currents in HVDC structures. They contain insulation, specialized touch materials, arc extinction strategies, manage circuitry, and auxiliary structures to ensure efficient and safe operation. Continuous improvements in contactor era, together with the improvement of strong-state HVDC contactors, are being pursued to further beautify the performance and reliability of HVDC structures.