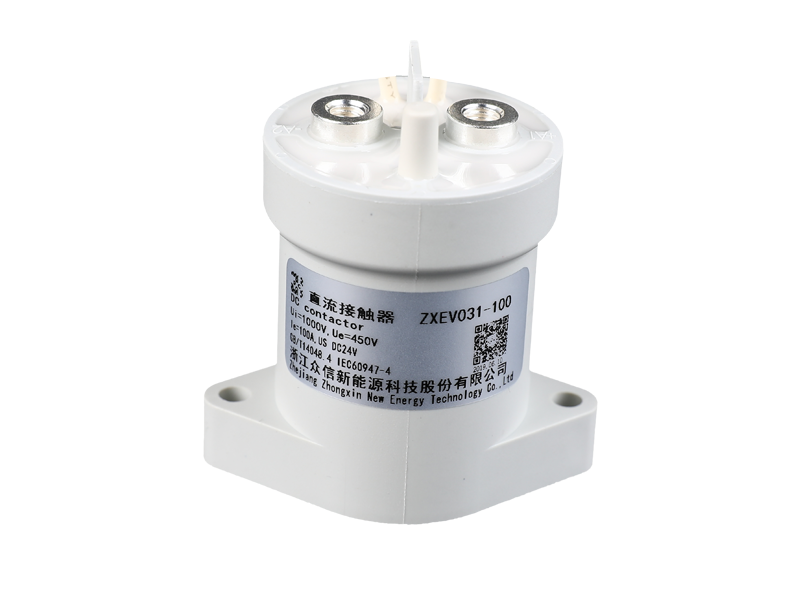

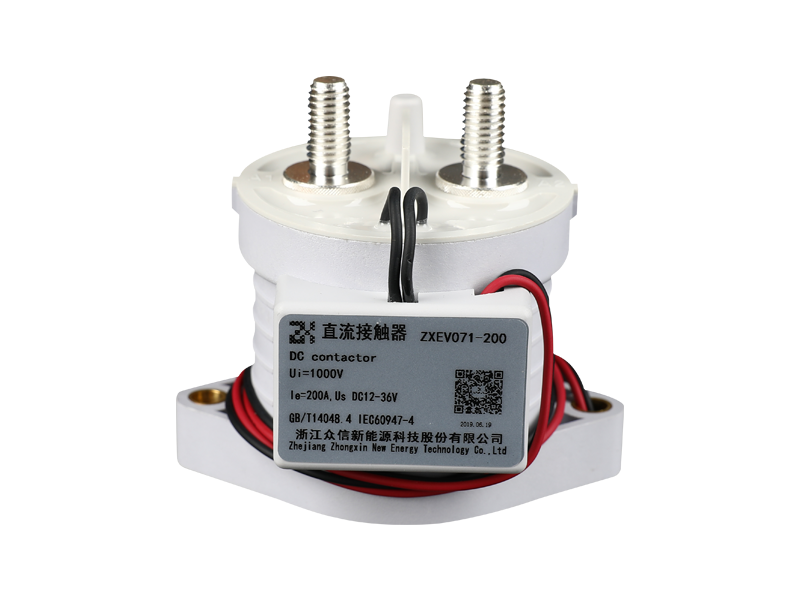

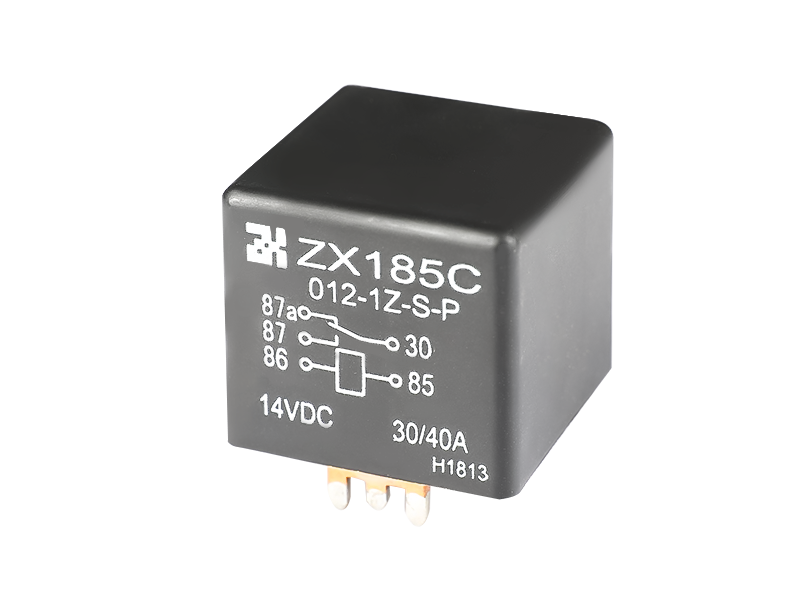

Ceramic excessive voltage direct current (HVDC) contactors are a type of electrical switch used in power structures to manipulate and isolate the go with the flow of energy. They are designed to deal with excessive voltages and currents, generally within the range of kilovolts and megavolts, making them an essential thing in lots of HVDC applications such as power transmission networks, renewable energy systems, and electric powered automobile charging stations.

Reliability is a important factor with regards to HVDC contactors, as any failure or malfunction can bring about disruptions to energy deliver, system harm, and protection hazards. So, it's far crucial to assess the reliability of ceramic HVDC contactors before their application.

One of the number one elements that contribute to the reliability of ceramic HVDC contactors is the selection of materials used for their creation. Ceramic substances own superb electrical insulation properties, excessive resistance to warmness, and desirable mechanical strength, making them suitable for high voltage programs. They additionally show off electric conductivity, which is appropriate for minimizing energy losses and stopping arcing, a phenomenon that may motive device degradation and failure. Due to these homes, ceramic HVDC contactors have the capability to offer dependable performance over prolonged intervals of operation.

Additionally, the reliability of Ceramic High Voltage Direct Current Contactors depends on the layout and manufacturing techniques worried. Precise engineering and meticulous fine control all through manufacturing make certain that the contactors meet stringent standards and specifications. The layout need to incorporate features such as robust touch surfaces, effective cooling systems, and green arc-quenching mechanisms to withstand the high voltages and currents encountered in HVDC systems. Adequate checking out tactics, together with electric, thermal, and mechanical assessments, can also enhance the reliability of those contactors with the aid of confirming their overall performance and sturdiness beneath diverse operating situations.

In phrases of reliability assessment, full-size laboratory checking out and subject trials are carried out to evaluate the overall performance of ceramic HVDC contactors. These exams simulate actual-international running conditions and assess factors consisting of touch resistance, switching speed, durability, and insulation capability. Detailed evaluation of the take a look at effects enables pick out layout upgrades and manufacturing upgrades that could similarly decorate the reliability of those contactors.

However, it's miles important to note that no electric element is entirely loose from the possibility of failure. Environmental elements including humidity, temperature variations, and contaminants can have an impact on the overall performance and longevity of ceramic HVDC contactors. Regular protection and tracking, including inspection of touch surfaces, inspection of insulation integrity, and cleaning tactics, are critical to make certain ongoing reliability. When necessary, alternative of worn-out or damaged components is crucial to preserve superior overall performance and prevent disasters.

In end, ceramic HVDC contactors offer a reliable answer for high voltage power manipulate packages. Their high-quality electrical insulation residences, resistance to warmth, and mechanical energy contribute to their durability and overall performance. Proper layout, awesome manufacturing procedures, substantial checking out, and everyday protection help maximize their reliability. However, ongoing monitoring and preventive upkeep are important to make sure endured dependable operation.