one, The working principle and characteristics of the relay

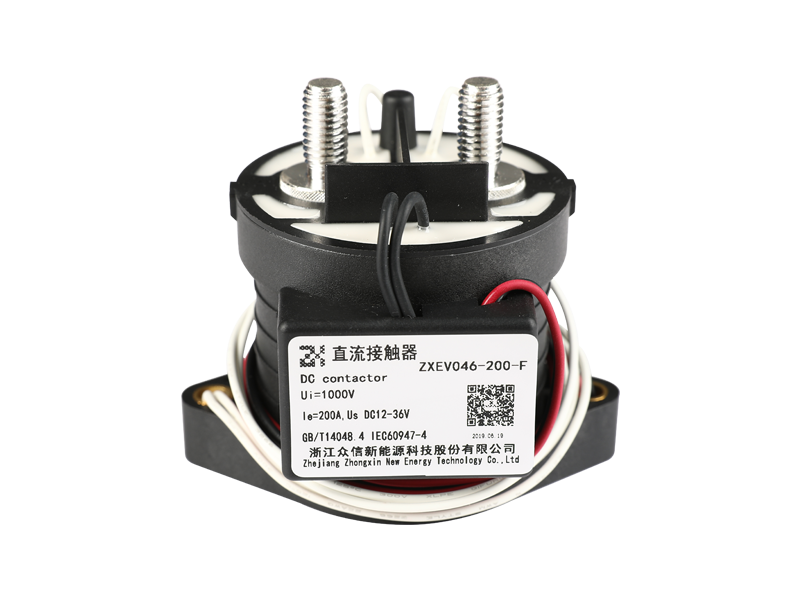

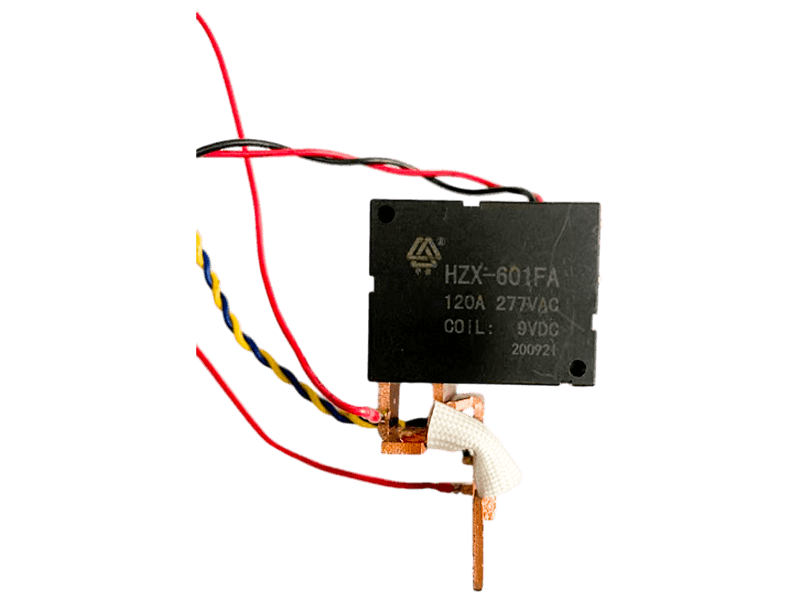

Relay is an electronic control device, it has a control system (also known as input circuit) and a controlled system (also known as output circuit), usually used in automatic control circuits, it actually uses a smaller current to control a larger An "automatic switch" of electric current. Therefore, it plays the role of automatic adjustment, safety protection, and conversion circuit in the circuit.

1. Working principle and characteristics of electromagnetic relay

Electromagnetic relays are generally composed of iron cores, coils, armatures, contacts, etc. As long as a certain voltage is applied to both ends of the coil, a certain current will flow through the coil, thereby generating an electromagnetic effect. The moving contact and the static contact (normally open contact) are sucked together. When the coil is de-energized, the electromagnetic attraction will also disappear, and the armature will return to its original position under the reaction force of the spring, so that the moving contact and the original static contact (normally closed contact) will be attracted. In this way, it is attracted and released, so as to achieve the purpose of conducting and cutting off in the circuit. For the "normally open and normally closed" contacts of the relay, it can be distinguished in this way: the static contact in the off state when the relay coil is not energized is called "normally open contact"; the static contact in the on state is called For "normally closed contact".

2. Working principle and characteristics of thermal reed relay

Thermal Reed Relay is a new type of thermal switch that uses thermal-sensitive magnetic materials to detect and control temperature. It consists of a temperature-sensing magnetic ring, a permanent magnetic ring, a dry reed switch, a heat-conducting mounting sheet, a plastic substrate and other accessories. The thermal reed relay does not use coil excitation, but the magnetic force generated by the constant magnetic ring drives the switch action. Whether the permanent magnetic ring can provide magnetic force to the reed switch is determined by the temperature control characteristics of the temperature sensing magnetic ring.

3. Working principle and characteristics of solid state relay (SSR)

A solid state relay is a four-terminal device with two terminals as input terminals and the other two terminals as output terminals. An isolation device is used in the middle to realize electrical isolation of input and output.

Solid state relays can be divided into AC type and DC type according to the type of load power supply. According to the switch type, it can be divided into normally open type and normally closed type. According to the isolation type, it can be divided into hybrid type, transformer isolation type and photoelectric isolation type, with photoelectric isolation type being the majority.

Second, the main product technical parameters of the relay

1. Rated working voltage

It refers to the voltage required by the coil when the relay works normally. Depending on the type of relay, it can be AC voltage or DC voltage.

2. DC resistance

Refers to the DC resistance of the coil in the relay, which can be measured by a multimeter.

3. Pull-in current

It refers to the minimum current that the relay can generate pull-in action. In normal use, the given current must be slightly greater than the pull-in current, so that the relay can work stably. As for the working voltage applied to the coil, generally do not exceed 1.5 times the rated working voltage, otherwise a large current will be generated and the coil will be burned.

4. Release current

It refers to the maximum current for the relay to produce a release action. When the current in the pull-in state of the relay decreases to a certain extent, the relay will return to the release state without power. At this time, the current is much smaller than the pull-in current.

5. Contact switching voltage and current

Refers to the voltage and current that the relay is allowed to load. It determines the size of the voltage and current that the relay can control, and it cannot exceed this value when used, otherwise it is easy to damage the contacts of the relay.

3. Relay test

1. Measure contact resistance

Use the resistance gear of the multimeter to measure the resistance of the normally closed contact and the moving point, and the resistance value should be 0; while the resistance value of the normally open contact and the moving point is infinite. From this, it can be distinguished which is a normally closed contact and which is a normally open contact.

2. Measuring coil resistance

The resistance value of the relay coil can be measured with a multimeter R×10Ω, so as to judge whether there is an open circuit in the coil.

3. Measure the pull-in voltage and pull-in current

Find an adjustable regulated power supply and an ammeter, input a set of voltages to the relay, and connect an ammeter in series in the power supply circuit for monitoring. Slowly increase the power supply voltage, and record the pull-in voltage and pull-in current when hearing the pull-in sound of the relay. For accuracy, you can try several times and calculate the average value.

4. Measure the release voltage and release current

The connection test is also the same as above. When the relay pulls in, gradually reduce the power supply voltage. When you hear the relay release sound again, write down the voltage and current at this time. You can also try several times to obtain an average release. voltage and release current. In general, the release voltage of the relay is about 10~50% of the pull-in voltage. If the release voltage is too small (less than 1/10 of the pull-in voltage), it cannot be used normally, which will pose a threat to the stability of the circuit. , works unreliably.

Fourth, the electrical symbol and contact form of the relay

The relay coil is represented by a rectangular box symbol in the circuit. If the relay has two coils, draw two parallel rectangular boxes. At the same time, mark the text symbol "J" of the relay in the rectangular box or beside the rectangular box. There are two ways to represent the contacts of the relay: one is to draw them directly on the side of the rectangular box, which is more intuitive. The other is to draw each contact into its own control circuit according to the needs of circuit connection. Usually, the same text symbols are marked on the contacts and coils of the same relay, and the contact groups are numbered. To show the difference. There are three basic forms of relay contacts:

1. The two contacts of the moving (H type) coil are disconnected when the coil is not energized, and the two contacts are closed after energization. It is represented by the pinyin prefix "H" of the ligature.

2. The two contacts of the dynamic break (D type) coil are closed when the coil is not energized, and the two contacts are disconnected after energization. It is represented by the word-breaking pinyin prefix "D".

3. Conversion type (Z type) This is the contact group type. This contact group has three contacts in total, that is, a moving contact in the middle, and a static contact at the top and bottom. When the coil is not energized, the movable contact and one of the static contacts are disconnected and the other is closed. After the coil is energized, the movable contact moves, making the original disconnected to be closed, and the originally closed to be in an open state to achieve the conversion. Purpose. Such a set of contacts is called a changeover contact. Use the pinyin prefix "z" of "Zhuan" to indicate.

5. Selection of relays

1. Understand the necessary conditions first

①The power supply voltage of the control circuit, the maximum current that can be provided;

②The voltage and current in the controlled circuit;

③ How many groups and what forms of contacts are required for the controlled circuit. When selecting a relay, the power supply voltage of the general control circuit can be used as the basis for selection. The control circuit should be able to provide enough working current to the relay, otherwise the relay pickup will be unstable.

2. After consulting the relevant information and confirming the conditions of use, you can look up the relevant information and find out the model and specification number of the required relay. If you already have a relay at hand, you can check whether it can be used according to the data. The last consideration is size fit.

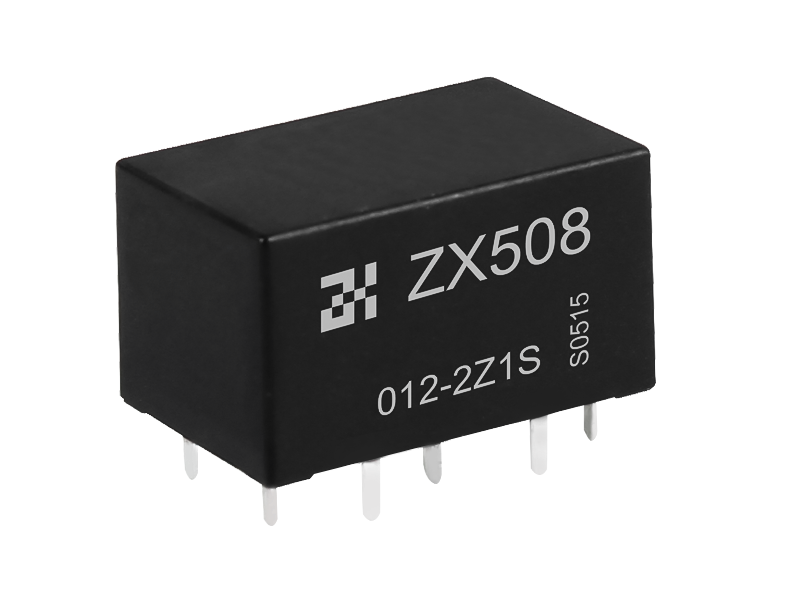

3. Pay attention to the volume of the appliance. If it is used for general electrical appliances, in addition to considering the volume of the case, the small relay mainly considers the layout of the circuit board. For small electrical appliances, such as toys and remote control devices, ultra-small relay products should be used.