The material used for

electrical relay contacts can significantly affect their durability and performance. Relay contacts are crucial components in electrical relays that are responsible for making or breaking electrical connections. The choice of contact material depends on several factors, including the application, voltage, current, and environmental conditions. Here are some common materials used for relay contacts and how they impact performance:

Silver Contacts: Silver is a popular choice for relay contacts due to its excellent electrical conductivity and low contact resistance. It is especially suitable for low-voltage and low-current applications. Silver contacts have good resistance to arcing and welding, making them reliable for many types of relays. However, they may be prone to oxidation in certain conditions.

Silver Alloy Contacts: To improve the durability of silver contacts, various silver alloys are used. These alloys can provide better resistance to arcing, reduce contact erosion, and enhance overall reliability.

Gold Contacts: Gold is known for its excellent conductivity and corrosion resistance. Gold-plated contacts are often used in low-current and low-voltage applications where reliability is critical. Gold contacts are less prone to oxidation and are suitable for applications that require very low contact resistance.

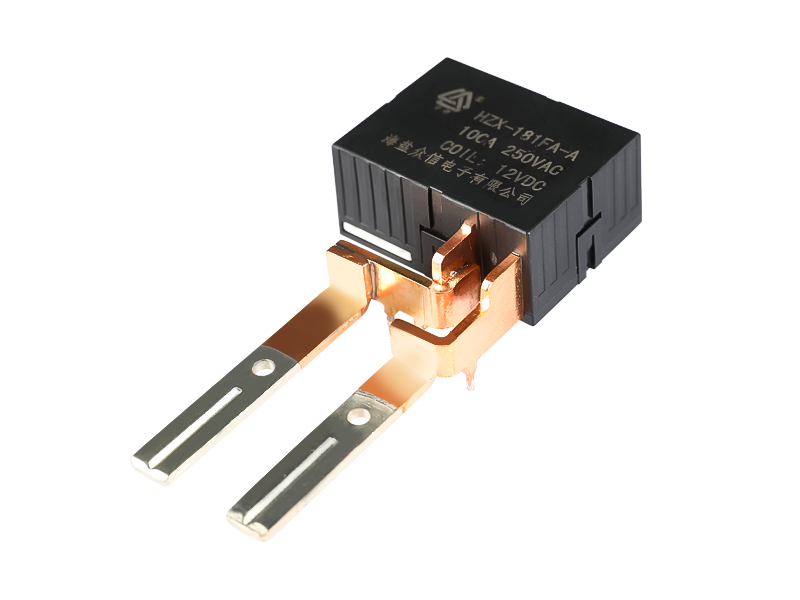

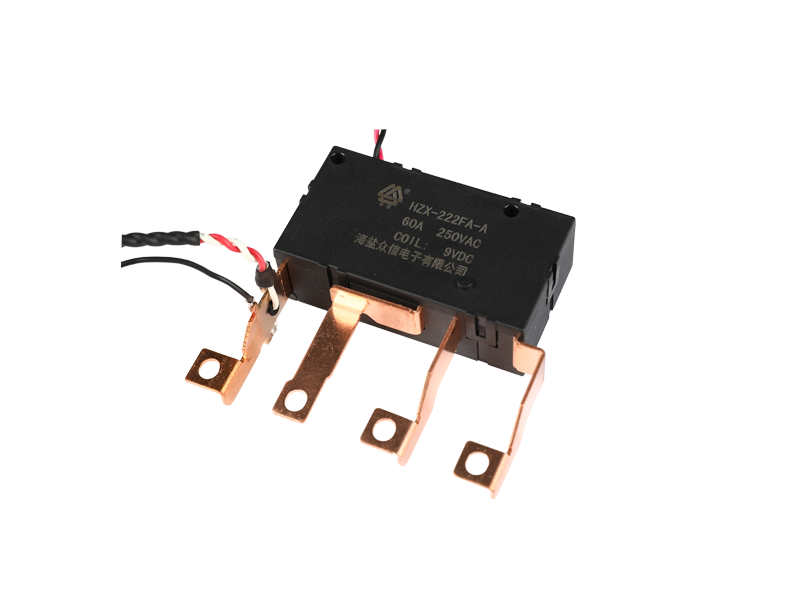

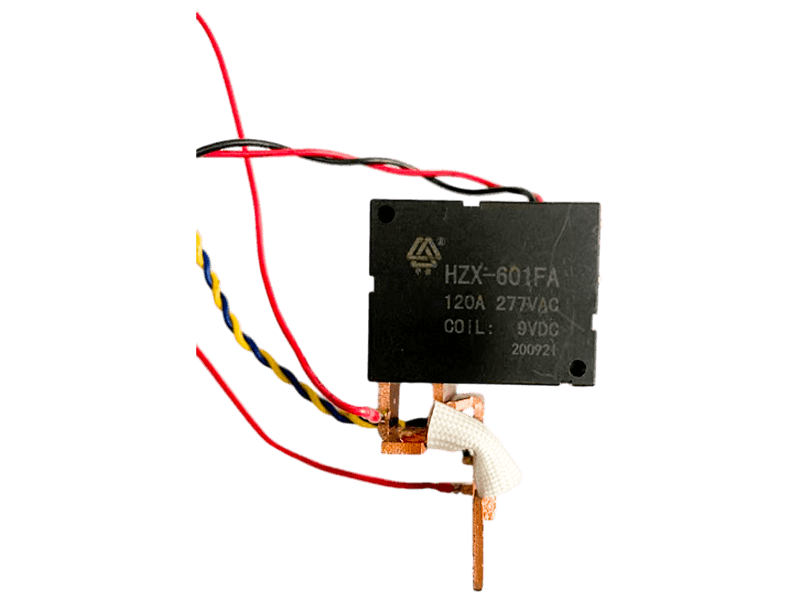

Copper Contacts: Copper is a cost-effective material with good electrical conductivity. Copper contacts are used in some relays for specific applications. However, copper contacts are more susceptible to oxidation and may require special coatings or treatments to improve their longevity.

Tungsten Contacts: Tungsten is a high-temperature, high-current contact material known for its resistance to arcing and wear. Tungsten contacts are used in relays that need to handle high currents and switching operations. They are durable but may have higher contact resistance compared to silver or gold.

Bimetallic Contacts: Bimetallic contacts are made by bonding two different metals with different coefficients of thermal expansion. They are commonly used in thermal overload relays and temperature-sensitive applications. Bimetallic contacts can bend or deform with temperature changes, opening or closing the relay contacts accordingly.

The choice of contact material should be based on the specific requirements of the application. Factors such as voltage, current, switching frequency, environmental conditions (e.g., humidity, temperature), and the expected number of operations (cycle life) all play a role in selecting the appropriate contact material to ensure optimal durability and performance of the electrical relay. Additionally, proper maintenance and care can also extend the life and reliability of relay contacts.