Electromagnetic latches are used in industries where it is necessary to control closing or opening of an electrical system from a remote location. This is done through electromagnetic relays or magnetic coils that make use of static power to generate alternating current. These systems are very convenient to have because they do not require manual labor, there is no need for power lines and they are very safe. It can be safely said that these systems are of great value to industry.

The basic function of this system is to automatically switch on and off depending upon the status of the relay. The main difference is that in the case of the Magnetic latching relays, the switching state is controlled either automatically or manually and typically only open or partially open state is dependent upon the function of temporary magnets. This means that if you are installing it in a system that requires a full circuit, it is best to consider using a high quality relay with high rating to prevent any short-circuits.

In the case where the switching state is manually controlled by a switch then the power supply requirements are minimal because the circuit does not require any active magnetic force. The open state simply signifies that the magnetic force is in its permanent state i.e. it is not being pulled down or pushed up. If the open circuit is required for some reason such as connection to a power source then the relay is usually required to remain in the open state to allow the power to flow.

In the case where the system requires an automatic switch to close, normally the magnetic latching relays have a two-way automatic switch. These types of systems operate using a dual-arm configuration whereby the open position of one arm is normally closed before the close position on the other arm. The open and close positions on the dual-arm relays will normally engage and disengage the system's safety mechanism. Due to this dual-arming capability, the system is able to provide an automatic closing as well as an opening when the two arms are separated by a distance of at least one and half inches.

The majority of these electromagnetic latching relays come with an integrated speed control unit which enables them to be controlled using either an analog or digital clock. The speed control provides the circuit owner with a means to program the desired speed of operation and thereby prevent overloads of electrical power that could cause damage to the equipment. For those systems without speed controls, the operator will typically need to program the desired open and closed speeds using a manual key or remote control.

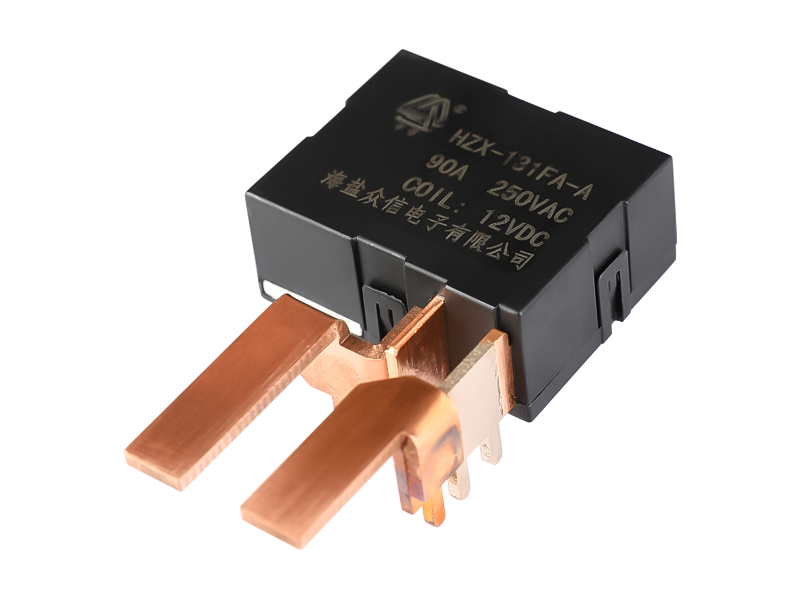

The two primary types of magnetic latching relays include the so-called active and passive types. An active latching relay utilizes the primary coil to attract and repel the magnetic field surrounding it. The coil is positioned in a location away from the motor so as to minimize the chances of it being negatively affected by the magnetic field around it. On the other hand, a passive magnetic latching relay uses the secondary coil to create a magnetic field that acts like a magnet. These systems have excellent load protection abilities and the ability to withstand extreme temperatures.