What is the structure of automotive relays

Update:03-12-2021

Automotive relays are widely used to control car startup, preheating, air conditioning, lights, wipers, EFI, fuel pumps, anti-theft, audio, navigation, electric fans, cooling fans, electric doors and windows, airbags, anti-lock brakes, suspensions In control and automotive electronic instrumentation and fault diagnosis systems, the number is second only to sensors.

The structure and working principle of automobile relay

The contact capacity of the control switch used in the car is generally small, and it cannot directly control the electrical equipment with a large working current. In this case, a relay is required to control its on and off.

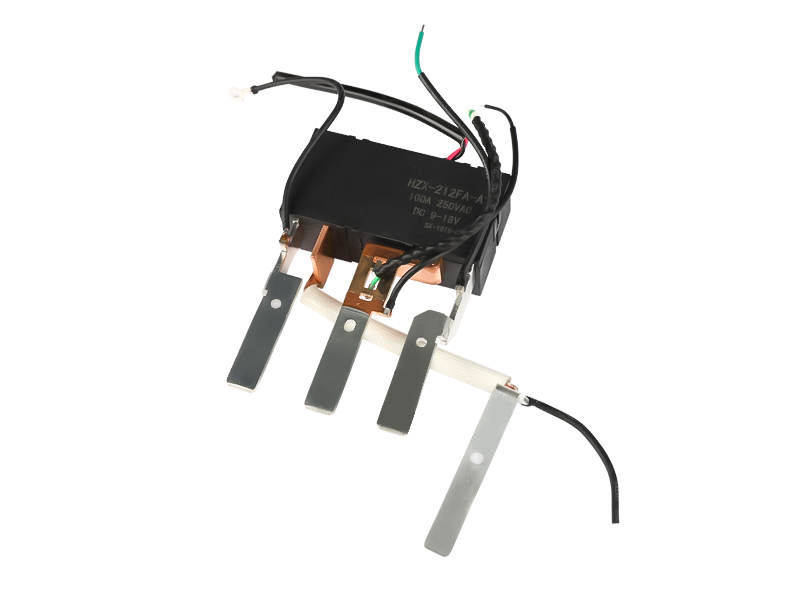

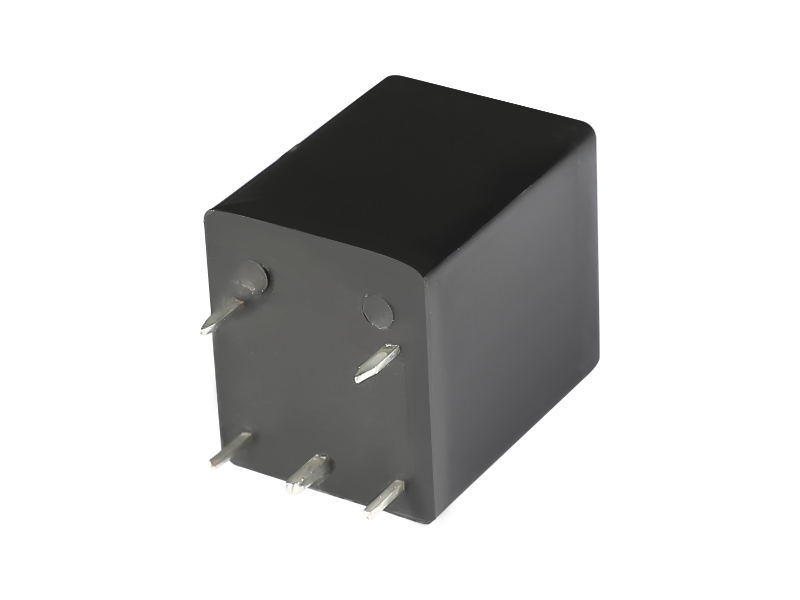

Automotive relays are generally composed of iron cores, coils, armatures, contact reeds, etc. As long as a certain voltage is applied to both ends of the coil, a certain current will flow through the coil and produce electromagnetic effects. Under the attraction, it overcomes the pulling force of the return spring and is attracted to the iron core, driving the moving contact of the armature and the static contact (normally open contact) to attract and close.

When the coil is de-energized, the electromagnetic attraction will disappear, the armature will return to its original position under the force of the spring, and the moving contact will be attracted to the original static contact (normally closed contact). Through such pull-in and release actions, the function of turning on and off in the circuit is achieved.

The structure of the relay

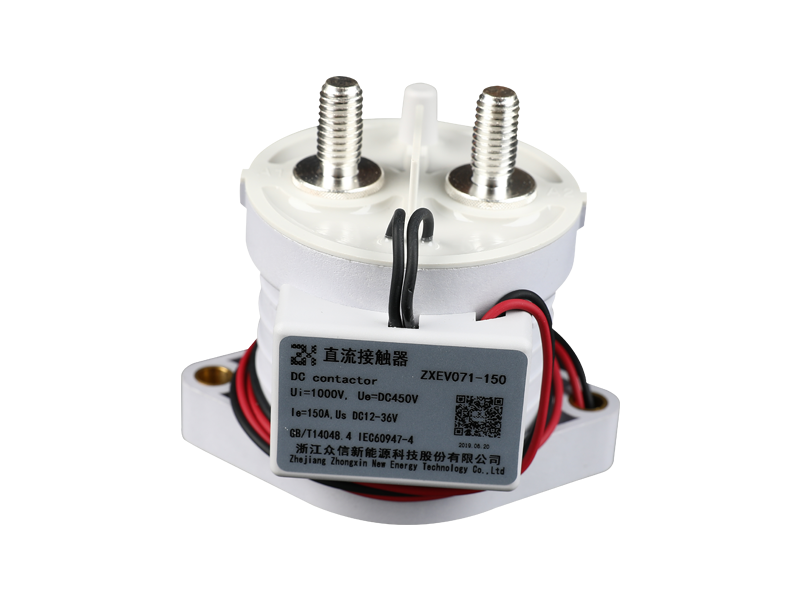

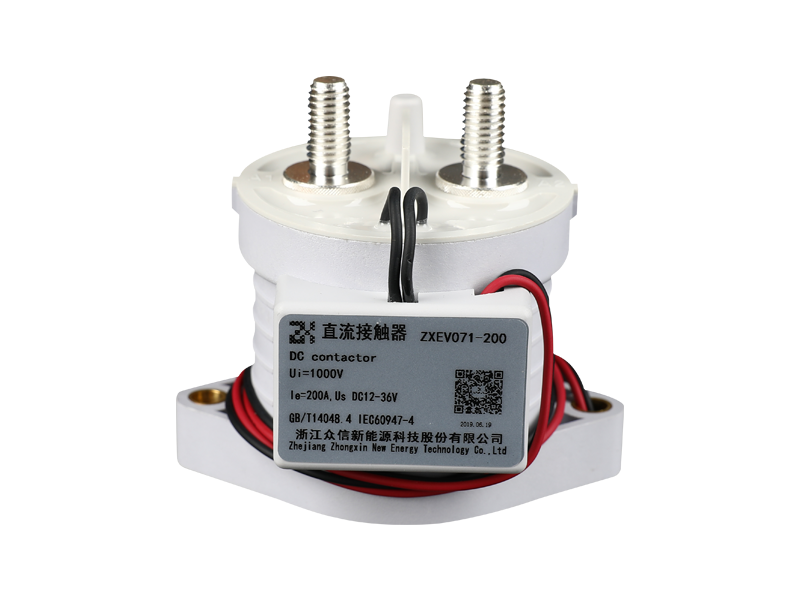

The relay is actually a switch in the circuit, but different from the traditional circuit switch, the core of the relay is to control the large current with a small current. It plays the role of automatic adjustment, safety protection, and conversion circuit in the circuit. It is a part of the automatic circuit. automatic switch".

As an automatic switch, the relay is not only controlled, but also plays a control role. It has a control system (also called an input loop) and a controlled system (also called an output loop).