HVDC transmission is the preferred technology for transmitting large amounts of electricity over long distances, as it offers several advantages over traditional alternating current (AC) transmission, including lower transmission losses, increased power capacity, and reduced electrical interference. However, HVDC transmission requires specialized equipment, such as HVDC contactors, to switch and control the flow of high-voltage DC power. Current HVDC contactor technologies are bulky, complex, and expensive, and are prone to failure due to the high levels of electrical stress and mechanical wear and tear.

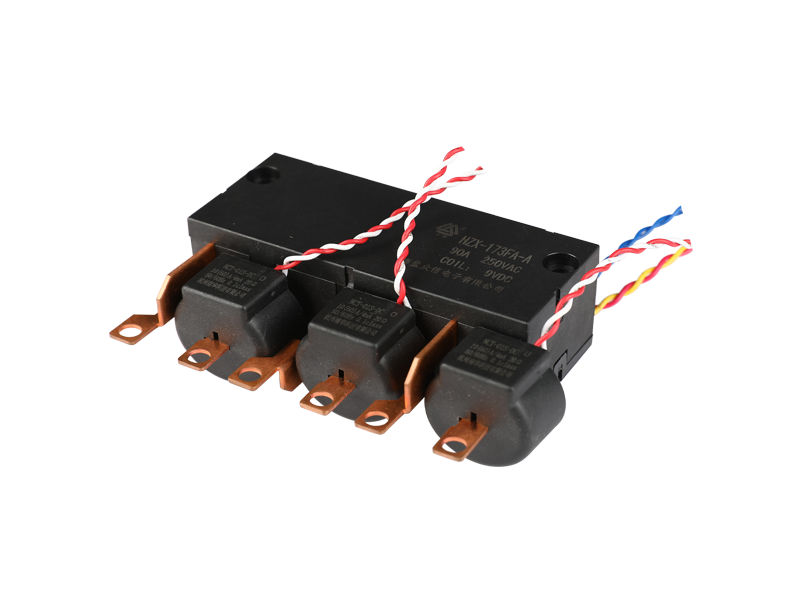

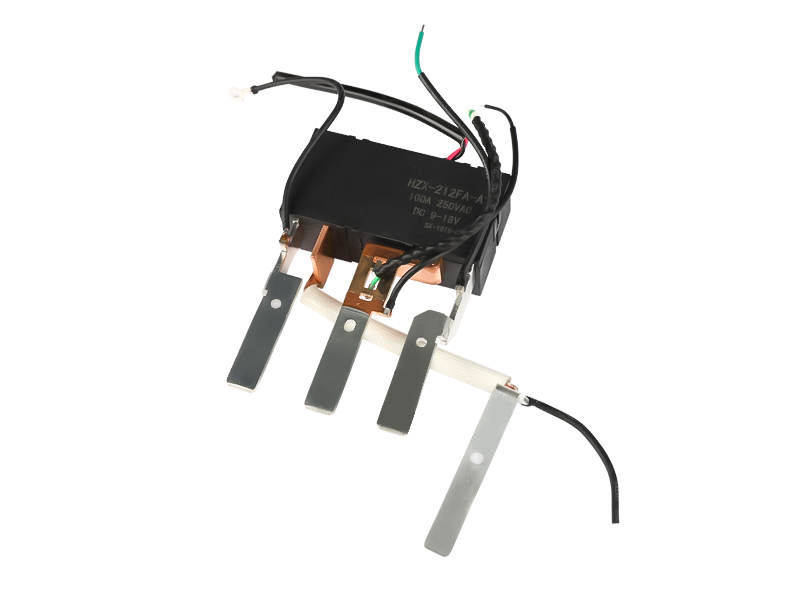

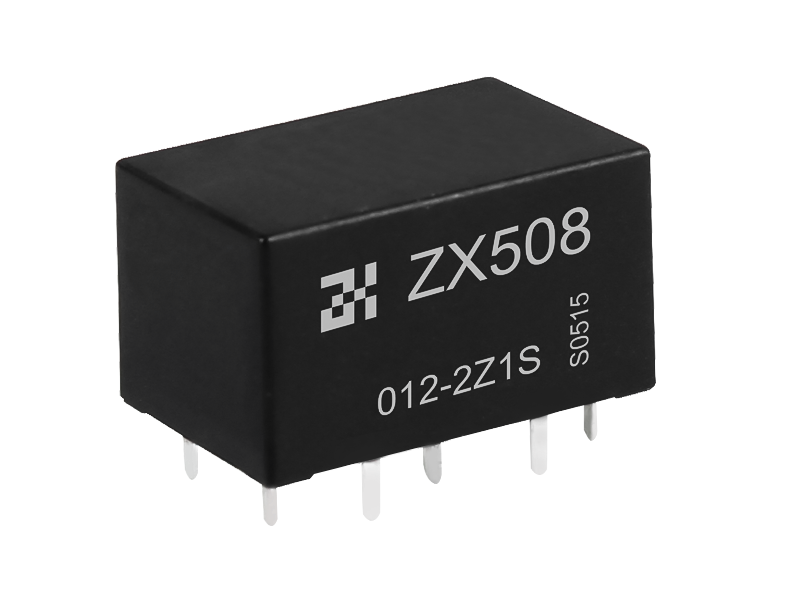

In addition, the new HVDC contactors are designed to operate at much higher voltages and currents than existing technologies, which enables them to transmit more power over longer distances with less energy loss. The contactors also feature a modular design that allows for easy maintenance and repair, and are equipped with advanced sensors and control systems that can detect and prevent faults and failures.

The potential applications of the new HVDC contactors are vast, and could have a significant impact on the energy industry and beyond. For example, they could enable the transmission of renewable energy from remote locations to urban centers, which could help to reduce the carbon footprint of electricity generation and increase energy security. They could also be used in electric vehicles and other transportation systems, where they could help to increase efficiency and reduce emissions.